Biomass Feedstock Conversion Interface Handling Computational Models

NLR has developed computational models that accurately represent the flow of complex biomass feedstock, allowing for the development of design charts for optimal biorefinery operation.

Upstream disruptions in the biorefinery conversion process—the handling of organic feedstock (e.g. corn stover, pine chips) in biorefinery processing chains—has been highlighted as a significant challenge in biofuels production. Low bulk density, and high compressibility and cohesion of the feedstock leads to poor flowability and jamming of equipment which disrupts the biorefinery conversion process.

Methodology

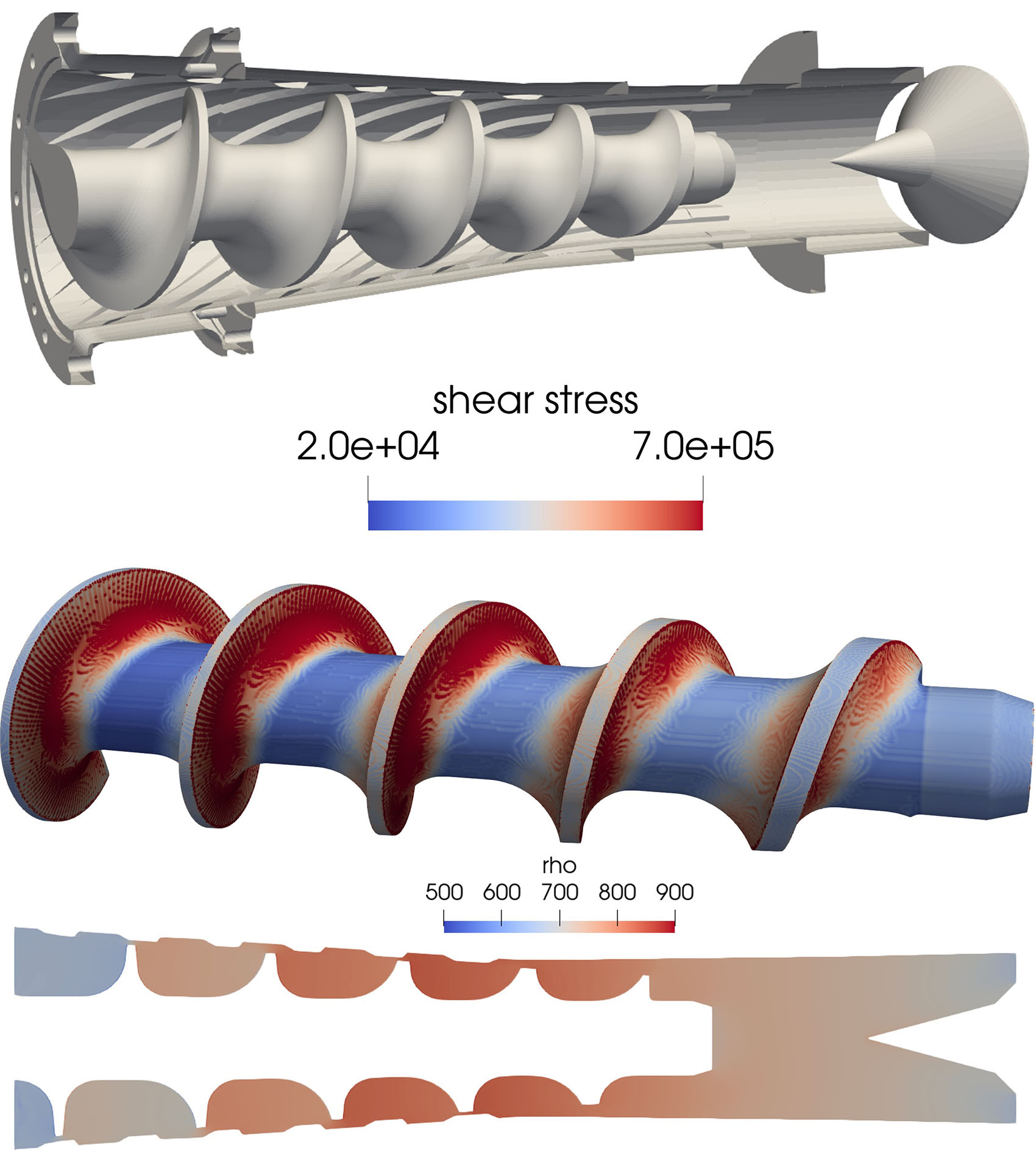

NLR focuses on the development of methods—including the discrete element, material point, and continuum-based methods—for accurately simulating the handling and flowability of organic biomass feedstock in coupled feed systems (e.g. wedge and conical hoppers, screw feeders).

We use the discrete element method along with models for complex particle shapes and cohesive properties to conduct high-fidelity investigations into ways to improve feedstock handling. Improved handling can help improve biofuel production and cost-competitiveness.

We have also developed a single-phase compressible, computational fluid dynamics solver that models both the density equation of state and the non-Newtonian viscosity for biomass slurries in compression screw feeders.

Read more about NLR's biomass conversion modeling.

Feedstock Conversion Interface Consortium Collaboration

The computational models were developed under the Feedstock-Conversion Interface Consortium, funded by U.S. Department of Energy's Bioenergy Technologies Office.

Publications

An Error-Controlled Adaptive Time-Stepping Method for Particle Advancement in Coupled CFD-DEM Simulations, Powder Technology (2021)

Numerical Analysis of Regular Material Point Method and Its Application to Multiphase Flows, NLR Presentation (2023)

Simulations of Biomass Compression-Screw Feeding Using a Compressible Non-Newtonian Constitutive Model, Chemical Engineering Science (2023)

Memory Access Optimization for Particle Operations in Computational Fluid Dynamics-Discrete Element Method Simulations, Particuology (2023)

Modeling Simultaneous Particle Shrinkage, Dissolution and Breakage Using the Modified Moving Grid Technique, Powder Technology (2023)

Development Team

NLR's feedstock-conversion interface development team includes Mohammad Rahimi, Hariswaran Sitaraman, and Ethan Young.

Contact

Share

Last Updated Dec. 4, 2025