Combustion Simulations for Aviation Fuels End Use

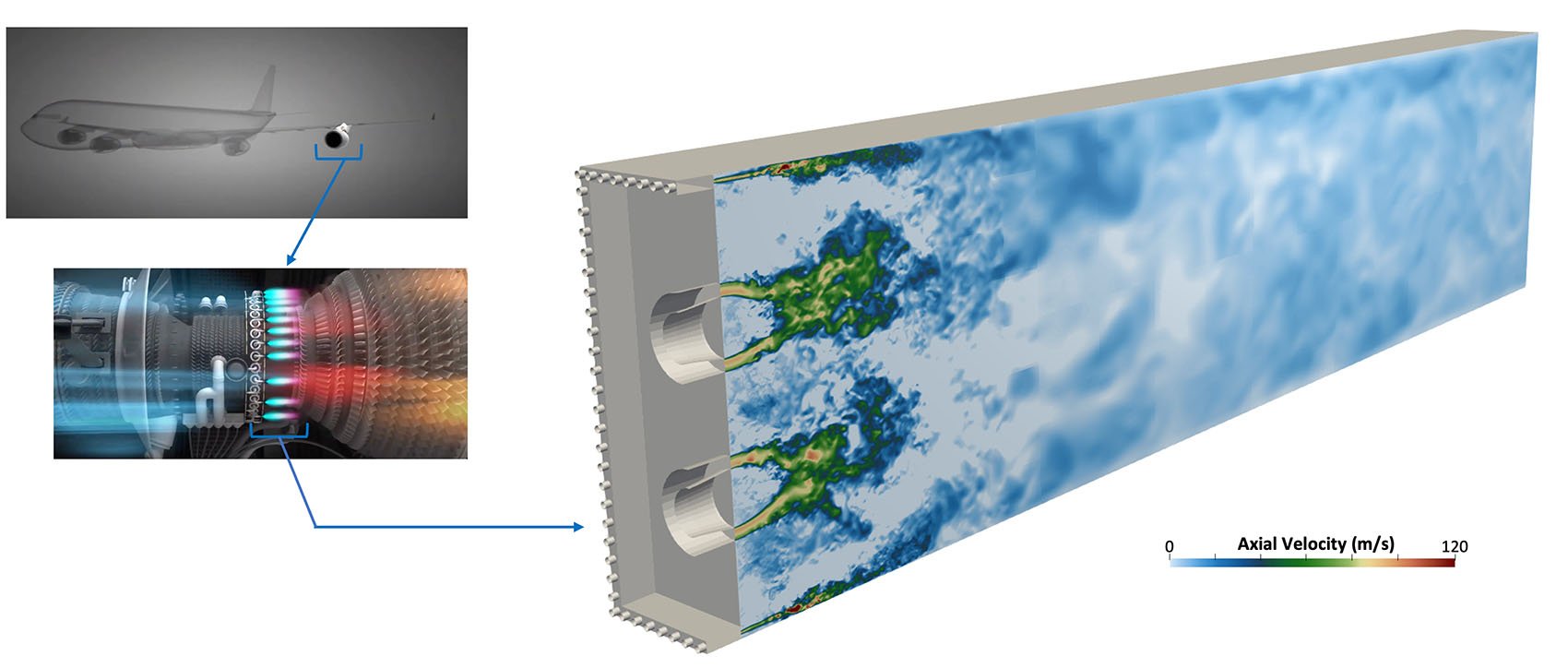

NLR uses high-fidelity combustion simulations to assess how the properties of aviation fuels affect performance, fuel economy, and reliability in aircraft engines and aviation gas turbines.

We are extending the Pele suite of combustion codes to include multiphysics processes involved in aviation fuel combustion and novel machine learning models that can drastically reduce computational cost. In collaboration with experiments done by Georgia Institute of Technology and GE Aviation, we are validating our simulations for combustion of both conventional jet fuel and aviation fuel in real gas turbine combustor geometries.

The combustion characteristics of aviation fuels often differ from those of fossil fuels. This is especially important if the SAFs are intended to serve as "drop-in" replacements—i.e., to be used in fossil-fuel-designed engines without any engine modification. The deployment and scale-up of aviation fuels is at risk given the uncertainty around their ability to meet certification requirements and perform as drop-in replacements.

Given that experimental studies on early-stage fuels are cost prohibitive, the fuel properties of aviation fuels must be related to combustor performance via simulations. These high-fidelity combustion simulations are used to investigate the effects of aviation fuel properties on combustion performance in aviation gas turbines.

Publications

Co-Optimized Machine-Learned Manifold Models for Large Eddy Simulation of Turbulent Combustion, Combustion and Flame (2022)

Development Team

NLR's aviation fuel end-use development team includes Marc Day, Sreejith N.A., Bruce Perry, Mohammad Rahimi, David Montgomery, and Shashank Yellapantula.

Contacts

Share

Last Updated Dec. 7, 2025