Inventive Thinkers at NREL Reach Record Number

NREL engineer Chris Deline came up with an idea for a device that would allow firefighters to quickly power down solar panels in case of a fire. Photo by Dennis Schroeder

The eureka moments can come fast and furious at the Energy Department's National Renewable Energy Laboratory (NREL), which last fiscal year racked up a record 169 inventions. Chris Deline's idea came to him while jogging, and from that sprang the potential to better protect firefighters.

Deline, a research engineer in NREL's photovoltaic performance and reliability group, jotted down his idea, a few paragraphs sufficiently describing his innovation that would be marked as a record of invention, or ROI.

"It's just a paragraph description with some schematics, and it's more to record internally that you've had an idea," he said.

The ROI process marks the first step in the process of protecting and eventually transferring federally funded research to the private sector. NREL's Technology Transfer Office (TTO) and Office of General Counsel work collaboratively to examine each ROI, and determine whether to pursue patent protection for each. An investment of patent protection is undertaken on about half of the ROIs submitted, according to Kristin Gray, NREL's TTO director.

Last year's ROI submissions, which also include the development of new software, easily topped the previous record of 134 set in fiscal 2011, and showed an increase from 127 in fiscal 2014.

Here are four examples of the ROI submissions filed in fiscal 2015.

Deline, who holds bachelor's, master's, and doctorate degrees in electrical engineering, came up with what's been dubbed the "PV Module-Level Remote Safety Disconnect." The idea is to keep firefighters out of harm's way when they're called to a home with rooftop solar panels. While electricity coming from power lines can be shut off at a junction box, the electricity generated by solar panels is always on as long as light is hitting the panels' surface. The National Electrical Code was revised in 2014 to specify all live wires connected to a solar panel must be able to be shut off within five feet of the panel.

Firefighters can easily cut the power to a non-solar house via the electric meter, but the presence of PV panels complicates matters. As much as 600 volts can be carried through the wires connected to a solar array, Deline said.

"My sort of eureka moment was trying to find a cheap, simple way to disconnect power within the array," he said.

The electricity generated by solar power relies on an inverter to convert the direct current (DC) into alternating current (AC) to use in a home.

Deline said using a "microinverter or some complicated circuits" would allow the solar array to be shut down, but their main function would still be to convert to sunlight to electricity. He wanted something that would separate the power conversion functions from a safety feature.

Deline thought of using the terminal that connects the solar panel to the frame of the module and inserting a sensing circuit there. (Two other terminals connected to the solar panel are negative and positive.)

"If you were to either mechanically or externally impose a short circuit or connection between one of those connectors and the frame, you could detect that locally within your junction box and then that would be the signal for it to disconnect from the grid and provide that firefighter safety," he said. "I was trying to find ways of using existing equipment that's already there in your PV system, just using it in a different way to provide additional functionality. It doesn't require additional wires. It doesn't require any different ways of configuring the system or adding components other than what would already be there normally. So you just add an additional sensing circuit within the PV module so that it can detect whether the frame is at the same potential as the module itself, and if that is true, then that is when the control causes it to go into a safe mode, effectively shorting itself out so that there's no power being exported."

Deline submitted his ROI—his first—in December 2014, answered some follow-up questions from NREL's TTO, and was able to file for a patent application in September 2015. "Most of the work was done by the folks at the patent group. They did a fantastic job. They did most of the work in terms of actually drafting the patent. I provided some technical details and they had some follow-up questions."

Deline, who's been at NREL since 2008, suggested other scientists on the campus take the little time needed to record an ROI.

"People should know it's pretty painless to write out a record of invention," he said. "If you have a good concept and you just want to take a couple of hours to write it up, most of the heavy lifting is done by others. That's great. That's a huge burden taken off the researcher."

Deline can't say what will happen to his idea next. But having an ROI, and a patent pending, will protect the concept until government funds or private money is made available to move it further past the idea stage.

NREL Research Fellow Robert Thresher, left, and Nathan Tom worked together to create a better way to capture energy from waves. Photo by Dennis Schroeder

Capturing Power of Water Has Its Challenges

Robert Thresher may be considered the wizard of wind at NREL, having been working in the field since 1973. At the laboratory since 1984, Thresher's credited with the buildup of what's now the National Wind Technology Center and the startup of the Energy Department's Water Energy Program. His longtime efforts at turning wind and water into renewable energy has now yielded an ROI titled "Wave Energy Conversion Devices with Actuated Geometry."

Just as wind turbines generate power, electricity can be generated by capturing the energy of waves. But therein is the problem.

"It's not like a wind farm where you can jump in your pickup and be there in a few minutes," Thresher said.

Wave devices typically look like buoys that move up and down in the water. The simplest type is a device that as the waves hit it pulls on a line attached to a generator on the ocean floor. That pulling motion creates the power, and that works fine except when a storm rolls in and the waves grow too large.

The pitch of blades on a wind turbine can be adjusted to reduce the amount of power generated. There's no need to build a giant generator to accommodate the highest wind speed possible, Thresher said, because those winds don't come along that often.

Something similar was needed to handle swells caused by powerful storm surges hitting a wave device. Thresher said the idea behind the ROI came from "kind of a group think" during a meeting with researchers experienced in everything from ocean engineering to control systems. "We thought to add something like a pitch control on a wind turbine."

Some existing wave devices have something that resembles a barn door with a hinge at the bottom. The waves move it back and forth. But control of a system like that is tricky; a large wave slapping against that door can overpower the generator, Thresher said.

He and his colleagues came up with the notion that the door should be more like flaps on a venetian blind, able to close fully when waves are optimal and to open to allow the excess energy to flow through.

"The flaps across it can open and close depending on wave conditions," Thresher said. "That allows you in very small or moderate waves to close all the flaps to get maximum exposure. As the wave height increases, you can open flaps to reduce the driving force and let a lot of energy go by. That allows you to operate over a wide set of conditions so you don't overpower your generator."

Control over when to open or close the flaps is the key to the idea working. Fortunately, Thresher's team included Michael Lawson, Yi-Hsiang Yu, and Nathan Tom, all of whom are among the principal developers at NREL of WEC-SIM, or Wave Energy Converter SIMulator. Funded by the Energy Department's Wind and Water Power Technologies Office, the software was developed through collaboration with NREL and Sandia National Laboratories. Using the WEC-SIM will help analyze how well the idea behind the ROI will work.

Better control of the wave loads hitting these devices could allow them to become a more economical source of renewable energy, said Tom, a postdoctoral researcher and the lead researcher on the wave device project.

"Wave devices are really heavy," he said. "We have a lot of steel. That is where we see the greatest cost savings will come. We believe the only way we'll have the cost savings is to have a system where the loads are even more controlled than they potentially are now."

Getting the wave device into the water will take some time, Thresher said, and that is expected to be in a test tank. A working prototype could take four or five years.

"It's truly in its infancy," he said.

Postdoctoral researcher Calvin Henard, left, and NREL Systems Biologist Michael Guarnieri received a record of invention for a way to put wasted methane to work. Photo by Dennis Schroeder

Evolutionary Idea Puts Methane to Work

"I wish there was a single eureka moment I could give you," said Michael Guarnieri, a systems biologist in NREL's biochemical process R&D group whose ROI has been dubbed "Methane Biocatalysts to Value Added Chemicals." "I think it's been more of an evolution."

The gaseous state of methane makes it incompatible for use as a transportation fuel, so it's typically burned for heat and power, or flared as an unneeded byproduct of producing natural gas. Methane stands out as the second most abundant of the greenhouse gases. To help combat that, the Energy Department issued a challenge to find a better use of methane, including the initiation of a Waste-to-Energy conversion platform and the Advance Research Projects Agency Energy (ARPA-E) REMOTE program—that stands for Reducing Emissions using Methanotrophic Organisms for Transportation Energy.

Those organisms are bacteria that can be genetically engineered to convert methane into materials that can replace the petroleum needed to make fuels or chemicals. That initial research done under the REMOTE program sparked the idea to use the methane captured from various waste streams—including from landfills and municipal solid waste.

"Instead of just flaring or burning that methane, we're now looking at the potential to convert it into fuel precursors and high-value co-products," said Guarnieri, who's been at NREL for almost six years. "In addition to hydrocarbon fuels, we have a couple of bioproducts that we've been targeting, one of which is lactic acid. We've successfully been able to biocatalyze methane to lactic acid, and we've also initiated a program to go from methane to a nylon precursor. Essentially this would be waste methane conversion to synthetic polymers."

Lactic acid can be used to make a bioplastic, meaning one that doesn't come from a petrochemical. Other types of organic acids, such as muconic acid or adipic acid, also can be made from methane to produce bioproducts such as nylon or polyurethane.

"We have actually already filed for a patent application for the muconic acid work," Guarnieri said. "It also encompasses the development of some novel genetic tools. Historically, what's been a hurdle working with these methanotrophic bacteria is they're not generally tractable or genetically malleable. We've invested a lot of energy upfront on implementing a whole suite of genetic tools that have enabled the downstream genetic engineering of these microbes."

Calvin Henard, a postdoctoral fellow working on the project, played a role in developing the genetic tools.

Since the ROI was recorded in May 2015, Guarnieri said, the target has been set to get the idea to a pilot scale or early-stage commercial scale by 2018. "We're hoping to advance this technology to a licensable state by the end of the third year. That would be a huge success."

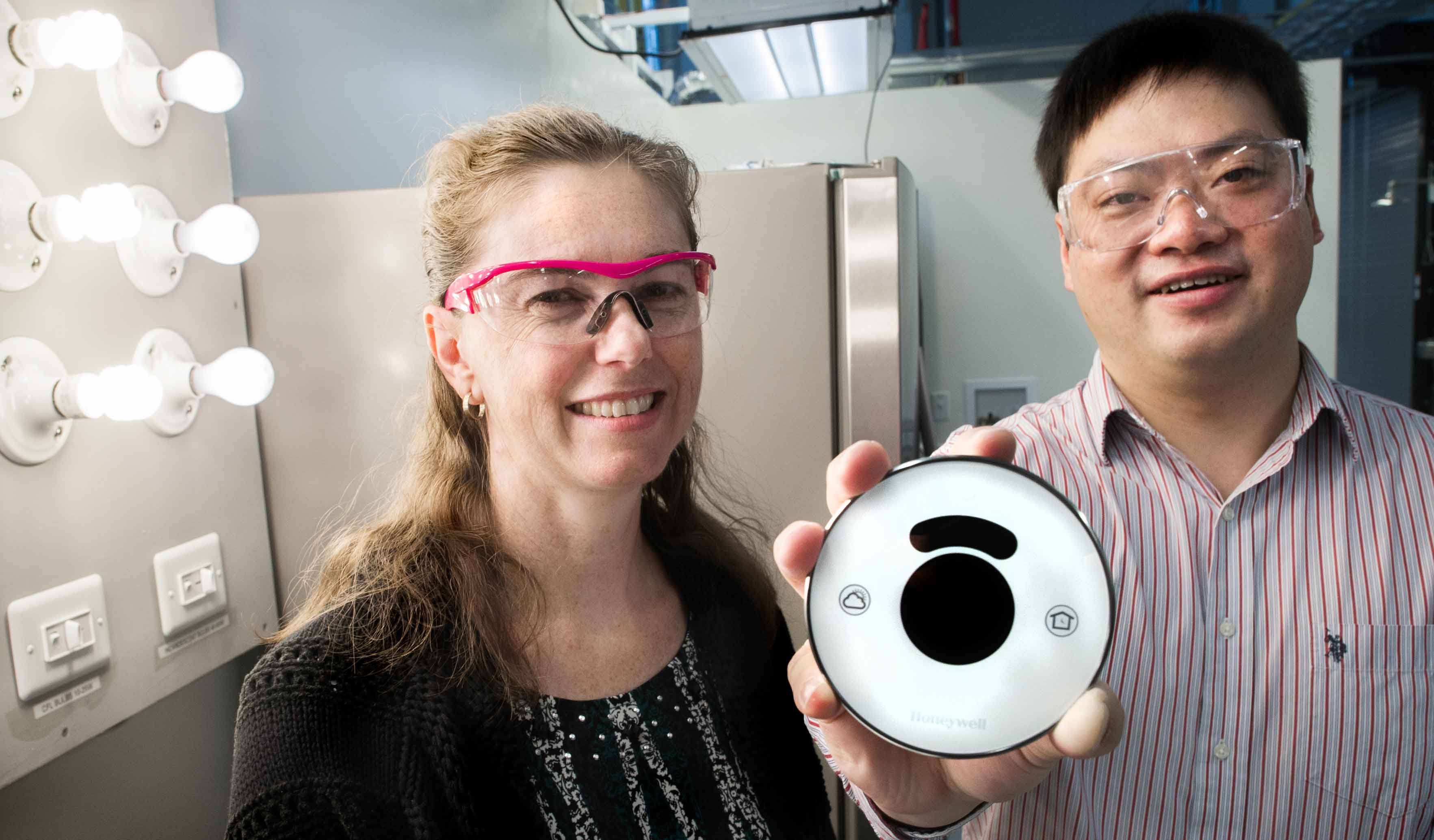

NREL engineers Annabelle Pratt, left, and Hongyu Wu hold a smart thermostat. The two came up with an algorithm that allows autonomous control of the various devices used in the home, from when to charge an electric vehicle to how often the air conditioner should come on. Photo by Dennis Schroeder

Software Gives Control of House to Owner

The ROI attached to Annabelle Pratt's name is titled "Home Energy Management System," but that's deceptively simple. Unlike existing smart devices that allow a homeowner to remotely control dishwashers or air conditioners, the software she and Hongyu Wu developed goes a step further in its sophistication.

Their software provides autonomous control of an entire house, handling everything from charging your electric vehicle for the morning commute to turning on appliances when utilities are charging the least for electricity. A real-time connection to weather forecasts and energy prices would allow the system to look into the future and meet the demand in the most cost-effective way and/or over a timeframe when the contribution of renewables to the generation mix is highest.

"Much of this is futuristic, anticipating what you would need," said Pratt, a principal electrical engineer in NREL's Power Systems Engineering Center. Wu, an engineer in the same group, said if the control system determines the price of electricity will be lower for the next hour, it could trigger more appliances to operate during that time frame.

Pratt and Wu both joined NREL in 2014. Wu wrote the software code, which at more than 5,000 lines took about six months. He had to take into account such factors as a weather forecast that proves to be wrong, and allow the software to make adjustments to cover errors and uncertainties.

Commercial buildings typically have energy management systems. That's important because utilities charge businesses based on the peak amount of electricity used during a billing period. Residential customers don't have peak charges yet, but that could change, Pratt said.

"Then you'd have to look at all your devices that you can control and manage them collectively so you can control your peak," she said. "We don't know if that's going to happen or when it will happen, but it is definitely one of the options people are discussing to reflect the real cost to homeowners of generating electricity."

With the software already drawing interest from companies, there are still a couple of challenges to be addressed. A user interface needs to be developed. The software also must be tailored so that it works across many different types of appliance manufacturers.

The day will come, Pratt said, when the software will find its way into homes across the country. It's just a matter of when.

"There is this momentum building, but when is it going to be mainstream is the question," she said.

— Wayne Hicks

Last Updated May 28, 2025