NREL's Biomass Analysis Tools Celebrate a Decade as the Industry Standard

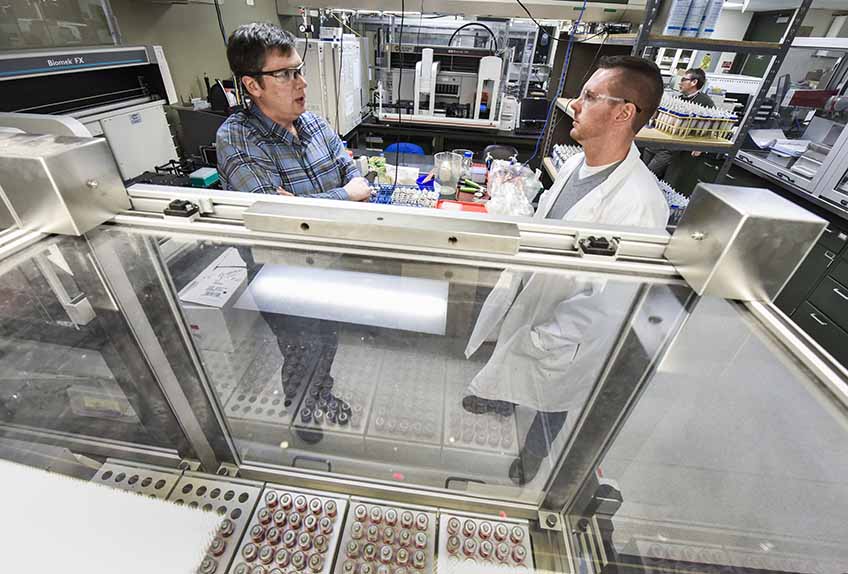

NREL researchers are working with High Throughput Recalcitrance Screening using the HTP Recalcitrance Screening Pipeline. Photo by Dennis Schroeder / NREL

Having the right tool for the right job at the right time is the goal of homeowners everywhere. And, when you find that perfect tool, you keep it. It’s no different in the bioenergy labs at the National Renewable Energy Laboratory (NREL) where, after nearly 10 years, the High Throughput Pipeline (HTP) tools have been delivering solid analysis not just for NREL, but for researchers around the world.

Just one of several sets of analysis-tools developed at NREL, the HTP rapidly compares biomass composition and conversion potential between thousands of different biomass samples. The objective? Understanding and manipulating biomass composition and recalcitrance. In other words, discovering which biomass feedstock, combined with the right enzyme, will readily give up its sugars for conversion into a biofuel or bioproduct.

Created at NREL with funding from the U.S. Department of Energy (DOE), the HTP continues to be the primary resource for biomass recalcitrance analysis both inside and outside the lab. In fact, the University of Georgia recently applied NREL's HTP in a study published in Nature Biotechnology earlier this year. The study, "Sugar Release and Growth of Biofuel Crops are Improved by Downregulation of Pectin Biosynthesis," describes how decreasing the expression of a gene called GAUT4 leads to a reduction in pectin, a component of plant cell walls that makes them resistant to the breakdown processes for biofuel creation.

"With the help of NREL's HTP tools, the GAUT4 study validated the critical role of pectin, a minor component by its abundance, but a key component in its role in plant cell wall architecture and recalcitrance," said Bryon Donohoe, bioenergy senior scientist at NREL and co-author of the GAUT4 study. "Understanding the role of pectin and other biomass components will only serve to expedite biofuel's path to commercialization."

Finding the Perfect Biomass Feedstock

The HTP is the world’s first high-throughput biomass assay system, coupling compositional analysis with thermochemical pretreatment and enzymatic hydrolysis assays to evaluate plant cell wall recalcitrance and provide data that can be used to identify those genetic and environmental factors that influence recalcitrance. The enzymatic recalcitrance assay system handles the severe temperatures, pressures, and pH conditions needed to screen for recalcitrance, and completes the screening simultaneously for hundreds of biomass samples.

In general, the enzymatic recalcitrance assay system uses automated solids handling to dispense small quantities of dried, milled biomass into thermochemically resistant 96-well reactor plates. Biomass samples are initially pretreated using acid, base, or water, followed by a thermal pretreatment.

After cooling and neutralization, enzymes are added to break down the biomass into sugars, primarily consisting of glucose and xylose. Enzyme-linked sugar assays are then conducted, and the two main sugars are colorimetrically quantified with the aid of liquid-handling robotics.

For critical analyses, the protocol can be adapted to measure the total biomass glucose and xylose composition to give a structural polysaccharide analysis of the material.

Built for Speed

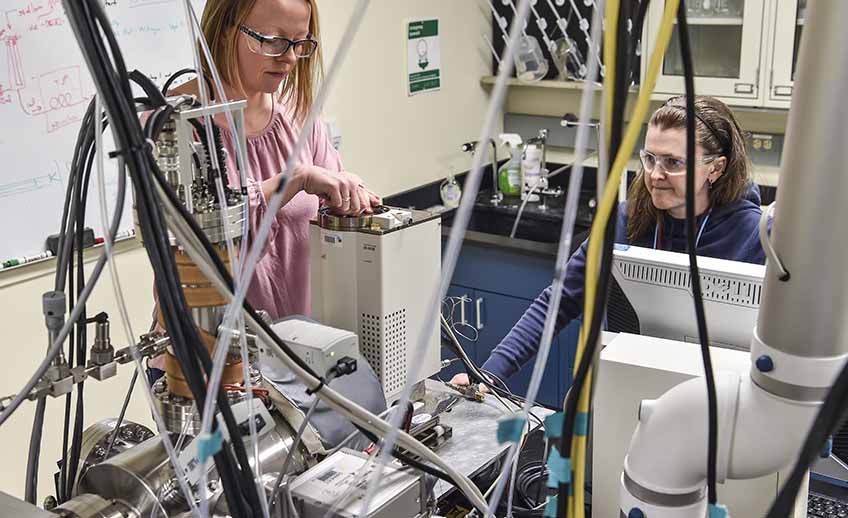

When the recalcitrance assay techniques are combined with HTP lignin analysis by pyrolysis-Molecular Beam Mass Spectrometry (py-MBMS), a very detailed comparative picture can be generated for plant scientists trying to find and understand new variants of biofuel feedstock crops. This tool heats the biomass sample to 500°C, breaking down the biomass chemical components. The components pass through a molecular beam mass spectrometer, which produces a spectrum that shows the mass-to-charge ratio of the individual components. By reconstructing the spectra, researchers get a fingerprint of most of the chemical components in the biomass sample.

Py-MBMS analysis has many positive attributes as it only requires a few mg of sample with minimal preparation and each sample is analyzed in about 1 minute. It is also capable of studying a range of biomass types and components including lignin, sugars and other components such as terpenes. Py-MBMS analyses have been included in hundreds of studies as part of the Bioenergy Science Center, as well as Advanced Research Projects Agency-Energy, and will continue to operate under the Center for Bioenergy Innovation supported by the Office of Science Biological and Environmental Research (BER) program.

NREL researchers work on High Throughput Pyrolysis-Molecular Beam Mass Spectrometry, which yields both lignin content and S/G ratio estimates from hundreds of samples per week using only 4mg or less of biomass material. Photo by Dennis Schroeder / NREL

Partnerships to Advance the Bioeconomy

Since its debut, the HTP has been utilized by dozens of collaborative partners in academia, industry and other national labs. Collectively, the HTP consisting of py-MBMS analysis and the sugar recalcitrance assay has analyzed approximately 100,000 samples and has been used in more than 300 studies.

Examples of such studies include The University of Pretoria's, "Network-Based Integration of Systems Genetics Data Reveals Pathways Associated with Lignocellulosic Biomass Accumulation and Processing," published by the Proceedings of the National Academy of Sciences and "Improving Wood Properties for Wood Utilization through Multi-Omics Integration in Lignin Biosynthesis," published in Nature Communications. The last study was conducted with help from Warren Edmunds, a student at North Carolina State University who worked at NREL through the DOE Office of Science's Graduate Student Research Program.

These studies completed using NREL's HTP tools have enabled a greater understanding of biomass composition and recalcitrance as it relates to the genome and other properties and traits of potential biofuel and biochemical feedstocks.

"The benefit of NREL's HTP tools for our partners is the speed at which researchers can complete analysis on bigger biomass batches more quickly," said Mark Davis, Biosciences Center Director at NREL. "This saves valuable research time and can help pave the way towards commercialization by making the entire biofuels and bioproducts process faster and cheaper."

Learn more about bioscience at NREL.

Last Updated May 28, 2025