Advancements in Catalytic Fast Pyrolysis Give Biofuels a Boost

National laboratory researchers demonstrate improvements in bio-oil yield through catalyst and process development

Researchers from the National Renewable Energy Laboratory (NREL), Pacific Northwest National Laboratory (PNNL), and Argonne National Laboratory (ANL) have identified an approach to improve the efficiency and reduce costs of biofuel production that moves beyond conventional strategies.

A culmination of years of catalyst development research, “Driving towards cost-competitive biofuels through catalytic fast pyrolysis by rethinking catalyst selection and reactor configuration,” was published in Energy and Environmental Science and details the catalytic fast pyrolysis (CFP) process in which researchers modified catalyst composition and reactor configuration to boost bio-oil yields.

Calvin Mukarakate and Kristiina Iisa co-authored the recent Energy and Environmental Science paper that highlights a new CFP approach with increased bio-oil yields and lower costs. Photo by Dennis Schroeder/NREL

Leveraging the Advantages of the CFP Route to Biofuels and Bioproducts

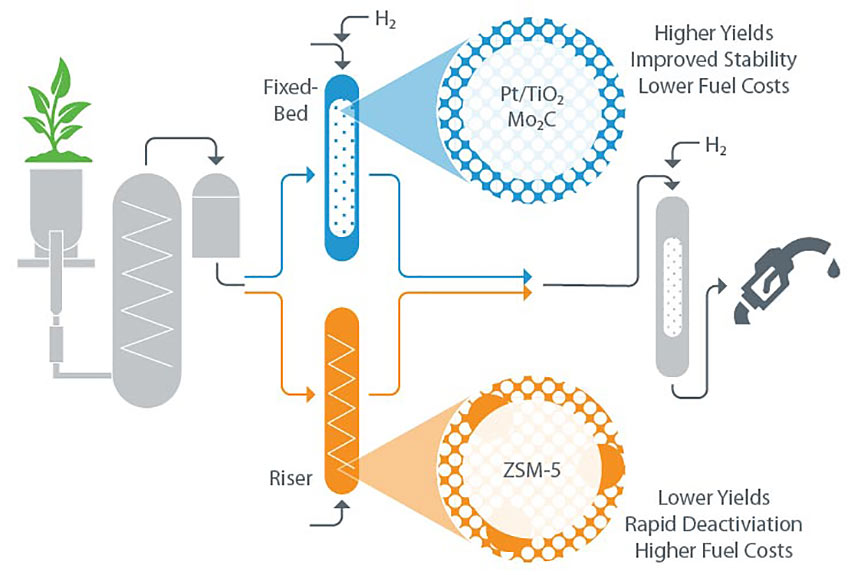

One benefit of CFP is its compatibility with a wide variety of lignocellulosic biomass. This feedstock flexibility, coupled with a diverse set of potential products, provides the foundation for a robust biorefinery concept. However, existing CFP processes use zeolite catalysts in riser reactors and suffer from lower than desired bio-oil yields. Recently, researchers from three national labs developed an alternative CFP approach that uses bifunctional catalysts in a fixed-bed reactor configuration and operates at atmospheric pressure. The modifications in catalyst type and reactor configuration have made all the difference in terms of increased bio-oil yields and lower costs.

“Zeolites form a lot of coke. As result they are used in a riser reactor system equipped with inline catalyst regeneration,” said NREL Senior Process Research Scientist Calvin Mukarakate, a co-author of the study. “In our case, we targeted a catalyst that doesn’t form a lot of coke and can achieve long reaction time on stream in a fixed bed reactor system. We noticed that, in addition to increased reaction times, we saw a significant increase in the yields of upgraded bio-oil compared to standard methods.”

New Approach Improves Overall Economics and Environmental Impact

A first-of-its-kind technical and economic evaluation of this alternative approach revealed a 50% relative improvement in overall carbon efficiency to fuel blendstocks, as compared to conventional CFP strategies.

“The techno-economic analysis included in the report provides a unique perspective,” said NREL’s Mike Griffin, a chemical engineer and lead author. “The calculations showed that our approach was cost-advantaged compared to conventional CFP processes. That’s really interesting because the catalyst—platinum on titanium dioxide—uses an expensive noble metal. However, the extended lifetime of the catalyst and the improved carbon yields of the process translated to an overall reduction in the fuel blendstock production cost.”

The environmental benefits of the process are also worth noting. Results of a life cycle analysis showed that total supply chain greenhouse gas emissions for the fuel blendstock is approximately 80% lower compared to conventional gasoline.

DOE Consortium Enables Valuable Teamwork

Working in tandem, this multilaboratory team discovered an alternative CFP approach—using fixed-bed reactors and bifunctional catalysts—that significantly improved bio-oil yields and the overall economics of the process.

All team members agreed that the project wouldn’t have been as successful without the close collaboration of researchers from the three national labs, all of whom are affiliated with Chemical Catalysis for Bioenergy, or ChemCatBio, a U.S. Department of Energy (DOE) national lab-led research and development consortium. Each lab had important and distinct responsibilities:

-

NREL led the modifications to the CFP process work, did the fractionation and fuel testing, and the techno-economic analysis.

-

PNNL hydrotreated the bio-oil and sent it back to NREL for further processing.

-

ANL performed the life cycle and environmental assessments.

Another advantage to the ChemCatBio collaboration was the ability to use the consortium’s newly developed catalyst cost estimation tool, CatCost, which guided the team to make proper decisions when selecting catalyst formulations.

“The tool helped us identify factors like the salvage value of platinum on titanium dioxide catalyst, which ended up having a significant impact on the overall catalyst cost,” Griffin said.

Up Next: Performance Enhancements and Reduced Costs

Co-author Michael Griffin prepares a batch of Pt/TiO2 catalyst that proved to be effective for the modified CFP process to convert biomass to biofuels and bioproducts. Photo by Dennis Schroeder/NREL

In addition to the positive economic and environmental impacts, this was the first time an integrated biomass-to-blendstock process had been demonstrated for this class of catalysts.

“We have not seen this full spectrum—going all the way from biomass to gasoline and diesel blendstocks and then measuring the fuel blendstock properties—in other literature,” said co-author and NREL Chemical Engineer Kristiina Iisa. “Measuring the quality of the fuel goes beyond what other research has done.”

The team analyzed the final blendstock product and discovered that although the properties precluded it from being a stand-alone fuel, the product would be appropriate for blending with petroleum-derived fuels. Griffin is quick to point out that even though this information was not what the researchers hoped for, it helped identify an important technical challenge, as the info was previously unknown to the scientific community.

Griffin, Mukarakate, and Iisa believe it is likely that additional performance enhancements and cost reductions can be achieved through further optimization of this early stage process. More research is required to further improve parameters such as catalyst stability, efficient regeneration procedures, and catalyst lifetime.

And with the goal of reducing costs, one thing the team is looking at is cheaper feedstocks. The current research uses clean pine, but future work will focus on forest residues and could include other feedstocks such as municipal solid waste and plastics.

These process improvements represent an important advancement in the catalytic fast pyrolysis technology and highlight a promising step forward for thermochemical conversion of biomass into fuels and products, thus enabling a sustainable U.S. bioeconomy.

Researchers developed a modified CFP approach using bifunctional catalysts in a fixed-bed reactor, which led to higher bio-oil yields and lower costs compared to the traditional process using zeolite catalysts in a riser reactor. Image courtesy of ChemCatBio

Last Updated Jan. 22, 2026