New Analysis Adds Realism to Renewable Energy Research

Of the countless factors that contribute to slow technology adoption, up-front costs and immediate savings tend to be the first and only drivers considered when a technology reaches commercialization. The National Renewable Energy Laboratory’s (NREL’s) Rebecca Hanes and her team set out to understand the complex issue of delayed adoption and “add more realism to energy savings projections,” she said.

A new technique developed by Hanes, a chemical engineer and lead author of the newest journal article to come out of NREL’s Advanced Manufacturing Program, could help energy analysts gauge which energy-efficient technologies provide the greatest benefits and guide future research, development, and deployment efforts.

Hanes and her team worked to account for how quickly and widely a technology will be adopted by manufacturers, and to incorporate this information into projections of energy savings over time. Their ground-breaking analysis, Quantifying Adoption Rates and Energy Savings over Time for Advanced Energy-Efficient Manufacturing Technologies, appears in the Journal of Cleaner Production.

This new analysis method incorporates a variety of technology characteristics that manufacturers consider when determining if an energy-efficient technology is worth the investment. These characteristics are divided into three categories:

- Relative Advantage: Up-front costs and immediate cost and energy saving

- Technical Context: Necessary internal effort and ease of replacement

- Information Context: Required external knowledge and customization.

Most energy analyses consider only relative advantages, which can lead to overly optimistic results that limit their ability to inform research and development decisions while hampering commercialization for beneficial technologies. “It’s not enough to look at how great a technology is. We need to assess how much effort is involved with actually using it,” said Hanes.

These technology characteristics are generic and applicable to any advanced manufacturing technology. The analysis procedure applies to a wide range of research areas and can be used to look ahead to what technologies could exist in the future and consider what level of technology adoption can realistically be achieved.

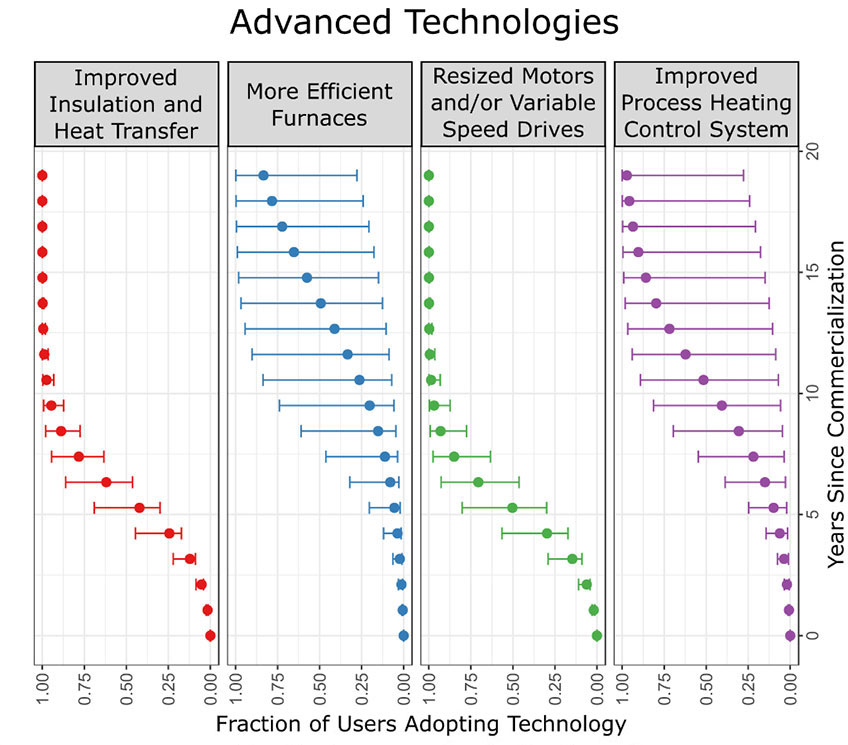

Bass curves are combined with energy savings data to calculate average process energy and average energy saved over time as technologies are adopted. Graphic by Rebecca Hanes, NREL

“Because there isn’t a lot of uncertainty information available, especially for newly developed technologies, it’s often not included in analyses,” said Hanes. “This analysis can incorporate several types of uncertainty and reflect analysts’ confidence in the available information. However, uncertainty does make results a lot harder to communicate to decision-makers who are looking for a definitive answer.”

This work was funded by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office and performed by researchers at NREL and Argonne National Laboratory.

Last Updated May 28, 2025