SpiderFLOAT Spins a Web of Offshore Innovation

Deep-Water Wind System Gains Further Momentum with ARPA-E ATLANTIS Funding

Deep-water offshore wind installations located in ocean depths greater than 60 meters could supply more than 1,200 gigawatts of energy-generating capacity to the electric grid. But despite this resource potential, relatively high capital expenditures for deep-water wind installations challenge offshore wind’s economic viability.

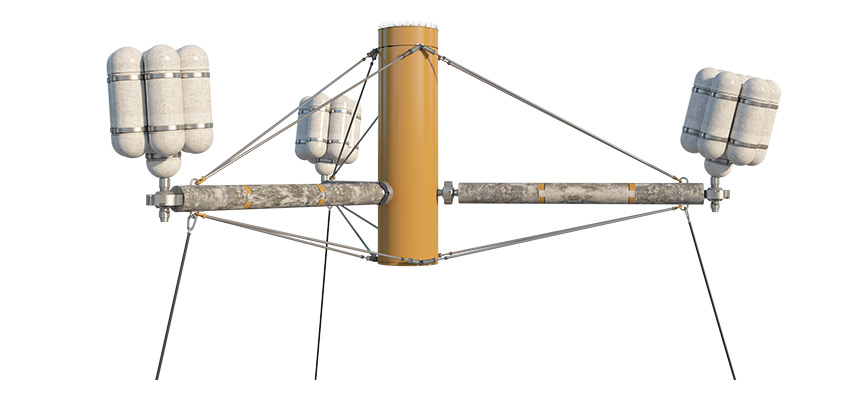

The National Renewable Energy Laboratory’s (NREL’s) innovative SpiderFLOAT technology—named for its modular components that resemble spider legs—has the potential to reduce costs by simplifying the construction and maintenance logistics for deep-water wind systems in challenging offshore marine environments.

SpiderFLOAT began as an internal NREL Laboratory Directed Research and Development project, and it has also been funded through the U.S. Department of Energy (DOE) Office of Energy Efficiency and Renewable Energy Wind Energy Technologies Office and DOE’s Energy I-Corps and Technology Commercialization Fund programs. Recently, SpiderFLOAT became part of DOE’s Advanced Research Projects Agency-Energy (ARPA-E) Aerodynamic Turbines Lighter and Afloat with Nautical Technologies and Integrated Servo-control (ATLANTIS) program to develop a 10-megawatt Ultraflexible Smart Floating Offshore Wind Turbine (USFLOWT). USFLOWT is one of three ATLANTIS projects awarded to NREL.

“USFLOWT will leverage SpiderFLOAT innovations, which tailor floating substructure designs to the challenges of offshore wind and make it possible to more effectively capture the planet’s abundant deep-water wind resources,” said NREL Research Engineer and USFLOWT/SpiderFLOAT Principal Investigator Senu Sirnivas.

SpiderFLOAT’s modularization and simplified mooring allow for partial on-site manufacturing and easy towing of the entire system for installation and maintenance. By minimizing construction activities at the installation site, SpiderFLOAT reduces environmentally detrimental activities such as pile driving typically required for fixed-bottom installations.

Both the SpiderFLOAT substructure and the larger USFLOWT system use innovative designs and materials best suited for the requirements of each component—combined with modular elements, local supply chains, automated and on-site manufacturing, and reduced materials requirements—to make offshore systems more cost competitive.

The USFLOWT project is a natural next step in the NREL research team’s work with industry partners to prepare the SpiderFLOAT system for commercialization. In the last year, the NREL research team updated the SpiderFLOAT model configuration for co-simulation, finalized validation matrixes, and prepared to conduct subscale model evaluations of the technology at a wave basin.

Last Updated May 28, 2025