Q&A With Alberta ("Birdie") Carpenter: How To Untangle Carbon From the Vast Web of Manufacturing and Supply Chains

Manufacturing Mastermind Series

Birdie Carpenter’s childhood was a constant migration. She was born in Guam, spent a few years in Saipan (the largest island in the Northern Mariana Islands in the Pacific Ocean), and, because her father was in the U.S. Foreign Service, grew up in Taiwan, Liberia, Sudan, Pakistan, and Somalia.

But Carpenter considers Saipan her true home. During her youth, the island had yet to install stoplights or see signs of a changing climate. If the term “carbon footprint” had been invented, Saipan’s would have been described as very, very small.

Today, Carpenter studies some of the world’s biggest carbon footprints, which are as complex, vast, and intertwined as her upbringing: the manufacturing sector and supply chains.

It takes money and energy to make each jug of milk, leather jacket, car, and everything in between. From mining for raw materials to manufacturing and shipping and all the way through disposal, every product comes with a complex carbon footprint. But these footprints are often tricky to untangle. That is where manufacturing mastermind Carpenter comes in.

Her tracking tools—like the Materials Flows through Industry modeling tool, which she helped design and now runs—identifies carbon hot spots in supply chains and offers strategies for industries to reduce emissions. Her work is helping transform the country’s too-often-linear product life cycles into a circular economy, in which used products do not end up in landfills but rather return to the beginning as valuable, recycled materials.

Carpenter has spent 12 years working as a senior environmental engineer at the National Renewable Energy Laboratory (NREL). So far, she has designed tools and methods to analyze COVID-19-caused manufacturing shortages, reduce plastic waste with the Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment (BOTTLE™) consortium, and study how novel, recyclable materials for solar panels and wind turbines could help build a 100% carbon-free energy sector.

Recently, Carpenter, who is a member of NREL’s Resources and Sustainability Group in the Strategic Energy Analysis Center, shared how she ended up in environmental engineering, what she is working on now, and how the next generation can join the cause.

What’s your scientist origin story? What drew you to science?

It's a little bit funny. Math and science were easier for me in high school, so my initial thought was to go into economics, because that’s what my dad was doing. But he said, “That's a terrible idea. You should be an engineer.” My dad was my first and best life mentor, so I took his advice and went into engineering.

Carpenter (in green) volunteered to help run NREL’s booth at a 2016 Girl Power event at Denver’s Natural History Museum. Photo courtesy of Alberta Carpenter

For your undergraduate studies, you ended up majoring in ocean engineering at the U.S. Naval Academy. Why did you choose that school?

As a high school student, I was invited to come visit. It was eye opening. For one, it was going to be a fully paid education with a job guaranteed (assuming you graduate). And they also had a couple of students shepherding us around who seemed way more confident and sure of themselves than I was at the time. That really resonated with me. I was like, “Oh this could be amazing! I'll come out a more confident person.”

Did you have any doubts along the way?

I wish I had taken more economics courses and maybe more art and history courses (for fun!). But I don't regret going into engineering. It's gotten me here.

What did you do after you graduated?

I worked in the Navy for five years, doing nothing related to ocean engineering. After the Navy, I was just following my nose until I ended up back home in Saipan, working on waste management in the Department of Public Works. That's when I figured out that environmental engineering was something I needed to do.

What triggered that change?

Waste management had so many challenges and issues. It was expensive, and it had substantial impacts on the environment. Traditional environmental engineering is more about designing landfills or wastewater treatment systems. While that knowledge is important to understand and we need to manage what we’re doing to the environment, I went off in a more generalist direction.

But you didn’t stay there, right?

I worked in Saipan for three years. But I knew staying there would limit my opportunities for professional growth. So, I went back and got my master’s degree in environmental engineering and then continued on for my Ph.D., because I was like, “If I don't do it now, I'm never going to do it.”

You earned a master’s degree from Carnegie Mellon University and a Ph.D. from the University of New Hampshire, both in environmental engineering. After that, you joined NREL and have been here 12 years. What were you working on when you first started, and how has your research focus changed over time?

I started with the buildings research group, managing the U.S. Life Cycle Inventory Database. My buildings knowledge is pretty limited, so I ended up connecting with Margaret (Maggie) Mann and other researchers in NREL’s Strategic Energy Analysis Center who were doing more crosscutting work on life cycle assessment. Eventually, I got pulled into supply chain analysis. That continued to grow, and, when Maggie moved to the transportation research group, I picked up the lead for the analysis work we were doing for the U.S. Department of Energy’s Advanced Manufacturing Office (AMO).

You’ve performed a good deal of strategic analysis work for AMO. Tell us about that.

Maggie was leading a project to create a tool to evaluate the supply chain, energy needs, and carbon emissions of U.S. manufacturing from beginning (raw material) to end (disposal). That became the Materials Flows through Industry Supply Chain modeling tool.

In earlier years, AMO mostly focused on how to reduce energy consumption within manufacturing facility gates. But the supply chain is also part of the industrial and manufacturing sectors. They are tightly integrated. And there’s a lot of evidence that the supply chain can have a much greater impact.

Many parts of the manufacturing sector and supply chain use products from the chemical sector, for example. That’s why AMO started thinking much more broadly, looking at the interconnections and the reliance of sectors on each other. Specific changes in the supply chain have a ripple effect; they could have really significant impacts. Or not. You don't know until you start looking at it from that holistic perspective.

Right. You’ve been looking specifically at how next-generation technologies and materials could affect the supply chain and cause ripple effects, right?

Exactly. We look at promising, early-stage technology and validate whether its benefits can potentially outweigh any negative impacts to the supply chain or not. So, for example, in a 2017 study on improving material and energy impacts in commodity supply chains, NREL Chemical Engineer Rebecca Hanes and I looked at carbon fiber frames for vehicles. Carbon fiber is lightweight and reduces the amount of fuel a vehicle requires. This is a great benefit. But if we look upstream, we know the production of carbon fiber is really, really energy-intensive. So, we evaluated different ways of producing carbon fiber to see if any could reduce energy use.

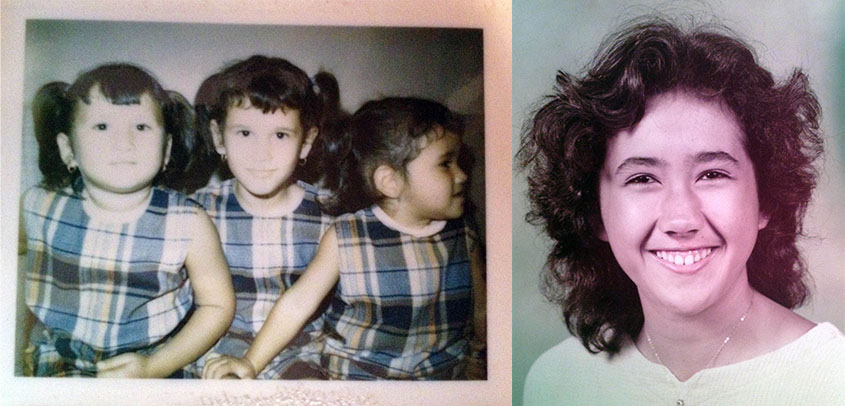

A young Carpenter sits with her sisters (left) and poses for a class photo. Photos courtesy of Alberta Carpenter

What do you see as potentially the biggest challenges still facing the supply chain today?

There’s the material consumption piece. Producing commodity materials for any type of product takes a lot of time, energy, and money. If we are more efficient in our use of materials then we can reduce the supply chain’s impacts, like carbon emissions.

And a lot of these next-generation technologies require materials that have limited supply or availability. This is a critical materials challenge. We can't just throw these materials away, so how do we make sure they’re available to the economy and future generations?

Also, manufacturing uses a lot of really nasty stuff and produces a lot of pollution. So, how do we do better? Ideally speaking, manufacturing should provide environmental benefits. I think this is where we need to go. How can manufacturing be part of ecosystem services so they're not degrading the ecosystem but rather bolstering it or improving it?

How do you think we’re doing at tackling these challenges?

There is some work being done, but we have a long way to go.

Throughout your NREL career, you’ve analyzed many different products, including plastics and solar panels. Are you more passionate about any one in particular?

They're all really important. Obviously, there's a lot of news about the terrible plastic waste in the ocean and how terrible we are about recycling it, especially single-use plastics. Plastic does provide value, like food packaging, which reduces our food waste. But we don't do a good job of managing it. How do we do that better?

Photovoltaics [for solar panels] are a different challenge. It's a different value, right? Solar energy is how we move toward a decarbonized economy. But the panels are not easy to recycle. So, how do you manage that? You could say the same thing for wind energy technology, which is going to help us decarbonize, but wind turbines are enormous. They're all unique and require different approaches, different technology solutions, and different logistical solutions to manufacture and recycle the materials. There's no one-size-fits-all solution.

What advice would you give to a young scientist who's considering a career in environmental engineering?

Make sure you’re passionate about the work because it's challenging and it can be tedious. As long as you feel it's valuable and important, you're in the right place. And be curious and open. It’s a two-way street. You're not only learning from your colleagues, but you're also teaching your colleagues, so you shouldn't be afraid to speak up. Be prepared to ask questions and be inquisitive about what you're hearing. We need all those voices to make sure we're not drinking our own Kool-Aid.

Interested in building a clean energy future? Read other Q&As from NREL researchers in Advanced Manufacturing, and browse open positions to see what it is like to work at NREL.

NREL is helping reduce carbon emissions and costs associated with manufacturing and supply chains while easing the transition to a 100% clean energy future. Our researchers analyze global clean energy manufacturing—including solar panels and wind turbines—examine the manufacturing industry’s material and energy needs, and track product life cycles to help reduce waste, increase recycling, and build a circular economy.

This article has been updated to reflect an editorial change made after its original publication.

Last Updated May 28, 2025