Microstructure Analysis ToolBox Changes the Game for Heterogeneous Material Modeling

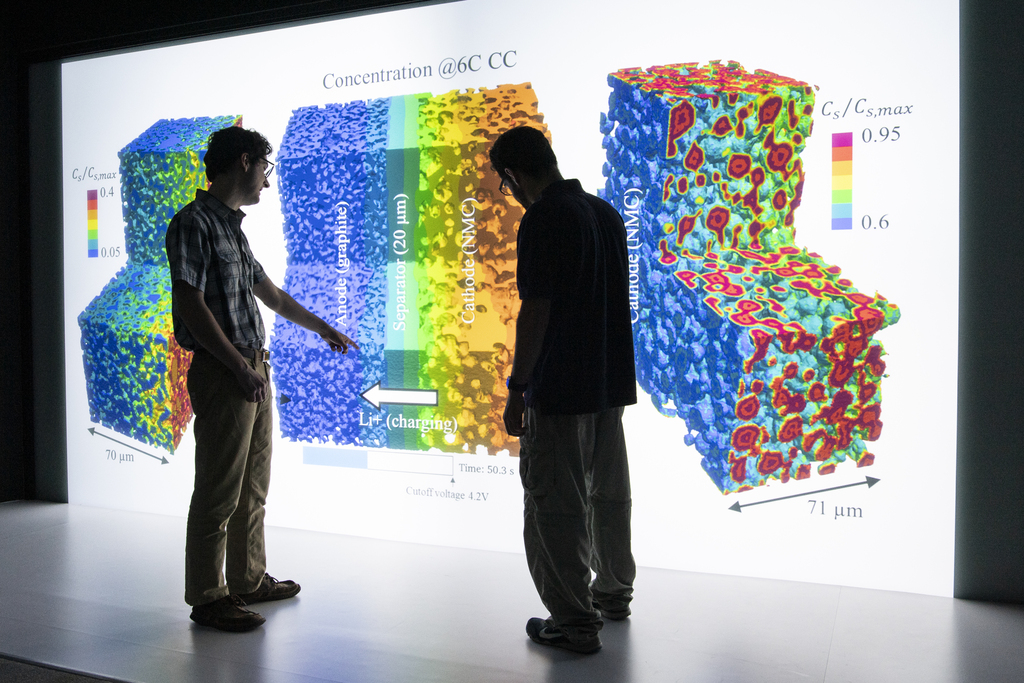

NREL researchers Francois Usseglio-Viretta (left) and Nicholas Brunhart-Lupo use the 3D Visualization Lab in the Insight Center at NREL's Energy Systems Integration Facility to work on the Microstructure Analysis ToolBox. Meshes generated with MATBOX are then used in other NREL electrochemical microstructure scale models to calculate, as illustrated here, concentrations during fast charging of lithium-ion battery electrodes. Simulations reveals non uniform utilization of the anode material (left), significant gradient within the electrolyte (center), and in-plane heterogeneities (all images) baseline one-dimensional macroscale models would otherwise neglect. Photo by Dennis Schroeder, NREL

The performance and safety of lithium-ion batteries (LIB) can be attributed to complex electrode microstructures. Microstructure analysis at the National Renewable Energy Laboratory (NREL) aims to apply in-depth knowledge of the electrodes to predict battery performances and identify optimal microstructure architecture to guide LIB development.

Microstructure-scale modeling carried out by NREL over the past five years has culminated in the newly released, open-source Microstructure Analysis ToolBox (MATBOX) dedicated to the meshing, numerical generation, segmentation, and characterization of three-dimensional heterogeneous materials, such as battery electrodes.

“In microstructure analysis, it is usually quite easy to calculate a specific property. However, it can be much more complicated to determine the factors that contribute to the margin of error for that result,” said Francois Usseglio-Viretta, an NREL researcher and lead designer of MATBOX. “Accurate analysis requires running hundreds of calculations, leading to a complex and time-consuming workflow. MATBOX automates this process.”

MATBOX leverages the existing MATLAB computing platform to increase understanding of the link between LIB electrode microstructures and performance. MATBOX focuses on providing microstructure parameters and three-dimensional meshes necessary for LIB modeling. In addition, the tool uses three-dimensional numerical generation for design space analysis and optimization. This easy-to-use application streamlines the otherwise time-consuming and complex tasks related to microstructure analysis for other materials.

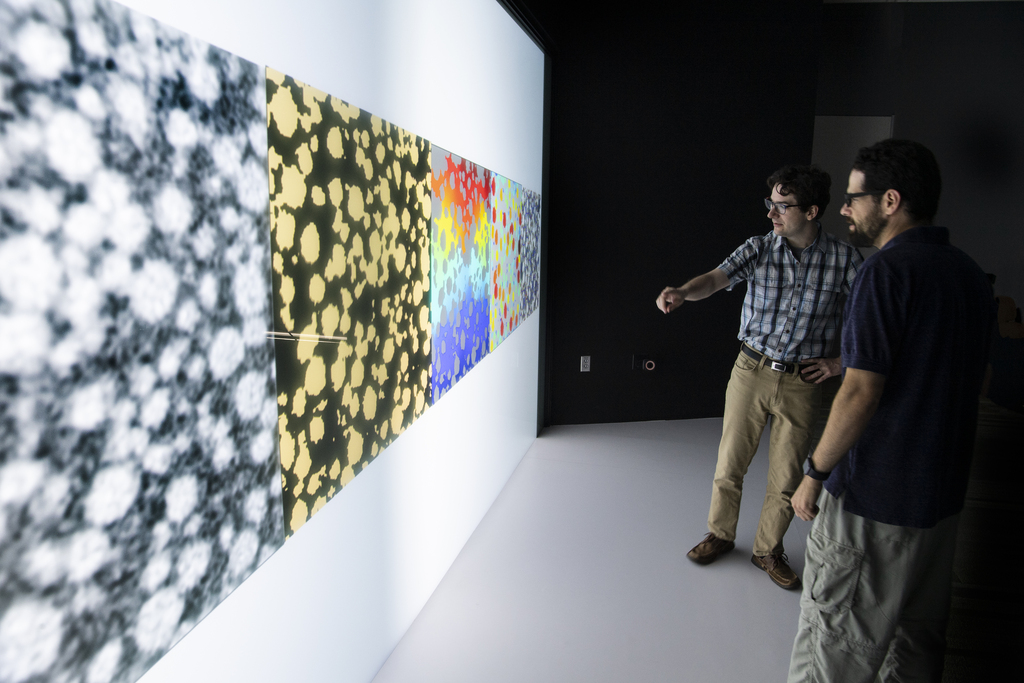

NREL researchers Francois Usseglio-Viretta and Nicholas Brunhart-Lupo discuss the microstructure segmentation and characterization workflow provided by the Microstructure Analysis ToolBox: from gray-level to binarized images, effective diffusion coefficient and particle labeling for size and morphology analysis is illustrated on lithium-ion battery cathode material. Photo by Dennis Schroeder, NREL

A key aspect of MATBOX is its complex graphic user interface and extensive documentation, allowing users to take full advantage of the toolbox capabilities. This interface ensures the tool is both user-friendly and relevant across material analysis applications. The tool is open source, allowing researchers from across industries to explore the full potential of MATBOX to guide experiments.

“Releasing MATBOX as an open-source tool was important to encourage continued collaboration across industry and other laboratories,” Usseglio-Viretta said. “We believe the tool will transform the field of heterogenous materials analysis, as it provides an all-in-one, user-friendly, customizable solution applicable to a large variety of materials.”

Early Results Bolster Existing Modeling Research

With its ability to support both microscale and macroscale electrochemical modeling, MATBOX is quickly becoming a critical step in the modeling workflow for the U.S. Department of Energy’s eXtreme Fast Charge Cell Evaluation of Lithium-Ion Batteries (XCEL) program. So far, MATBOX has allowed XCEL researchers to characterize various electrodes manufactured by Argonne National Laboratory at its Cell Analysis, Modeling, and Prototyping Facility and identify promising electrode architectures tailored to fast-charge applications for electric vehicles.

However, MATBOX’s impact surpasses electrode research alone. Researchers at NREL’s Renewable Resources and Enabling Sciences Center are using MATBOX to compare the differences in porosity and pore structure of wood and biochar to increase the accuracy of renewable energy production modeling for pyrolysis. Externally, the University College London, University of Alabama in Huntsville, and Sandia National Laboratories are using MATBOX to expand research into battery technologies, such as low-cobalt cathodes.

Learn more about NREL’s transportation and mobility and energy storage research.

Last Updated May 28, 2025