What Is the Recipe for First Commercial Success for Clean Energy Technologies?

Analysts Study Lab-to-Market Pathways for Clean Energy Technologies

Research and development (R&D) has been vital to developing new clean energy technologies. Yet for technologies to advance from the research lab to viable commercial products many obstacles must be overcome. To replicate such pathways for future clean energy technologies, the critical period between research demonstrations and first commercialization is important to understand.

Analysts from the National Renewable Energy Laboratory (NREL), Joint Institute for Strategic Energy Analysis (JISEA), and U.S. Department of Energy (DOE) analyzed case studies of the first commercialization of four clean energy technologies: thin-film photovoltaic (PV) solar panels, wind turbines, dual-stage evaporators for refrigeration, and fuel cells for material handling equipment.

Findings across the case studies—published in a Frontiers in Energy Research article—revealed three components that are common to successful advancement to commercialization: (1) a good fit among public-private partnerships, R&D infrastructure, and the technology itself; (2) appropriate alignment of government regulations, R&D priorities, and market forces; and (3) the right timing between technology readiness and market opportunity.

“These findings can help inform clean energy investment decision-making, maximize benefits from R&D, and advance transition to a productive, low-emission future,” said Wyatt Merrill, DOE technology manager and co-author.

Thin-Film Solar PV: Solutions To Meet Standards Inspired Technological Breakthroughs

From the 1980s to the early 2000s, DOE funded research on thin-film PV cells, including partnership programs led by NREL and direct funding to solar manufacturers like First Solar.

The innovation ecosystem had enabled the demonstration of a record-breaking (at the time) 15.8% cell efficiency and a new manufacturing technique that allowed First Solar to produce thin-film PV modules at a larger scale—a breakthrough alternative to the slower, costlier manufacturing process at the time.

With greater device efficiency and scalable manufacturing procedures in place, R&D focus shifted to testing and validation. Through support from Arizona State University and NREL, First Solar proved in 2003 that its modules were ready to enter the solar market.

The following year, DOE funded independent studies on thin-film PV module emissions and recyclability, allowing First Solar to meet Germany’s energy performance and regulatory requirements and enter the market that same year. In doing so, First Solar introduced a module takeback program in 2005—a major turning point for thin-film PV commercialization.

“The thin-film PV case study shows the importance of addressing regulatory needs within the technology’s first major market,” said Marie Mapes, DOE technology manager and co-author. “In addition, establishing a proven product at a price and time when the market was ready for it led to its early success.”

Innovation Ecosystem Funded Advanced Wind Turbine Blade Design

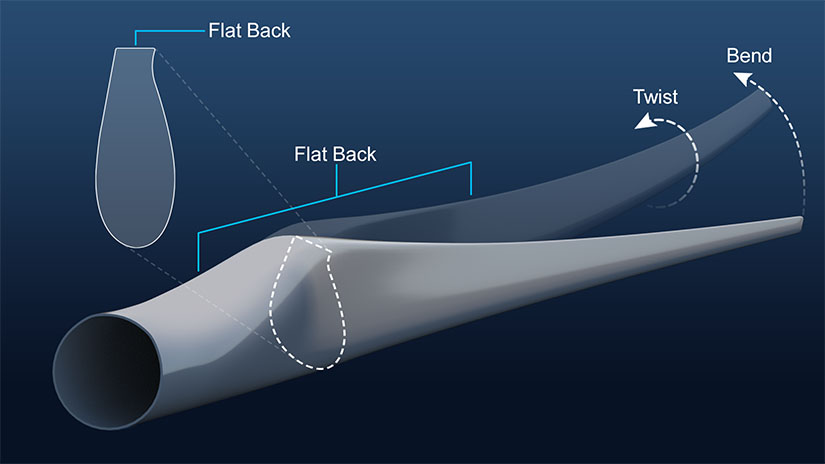

Wind turbine blade lengths have historically increased over time to capture more energy; however, heavier blades cause higher loads and increased costs. From 1995 to 2008, universities, national laboratories, and private companies funded advances to improve wind turbine blade design.

Private-public support and open innovation, which are indifferent to a specific approach or design solution, led to the parallel development of flat-back and bend-twist blade designs. These blades, which are substantially longer, capture more energy without adding significant mass or compromising reliability. And these innovations have been credited by wind technologists as some of the largest contributing factors to decreased wind energy prices, which are down by more than 60% since 2009. In absence of patents protecting the innovations, private companies incorporated the designs into their own proprietary blades and analysis tools, which accelerated commercialization. Today, most major commercial turbines include elements of flat-back and bend-twist designs.

Efficiency Standards Established First-Market Dual-Evaporator Refrigerators, Sparked Additional R&D

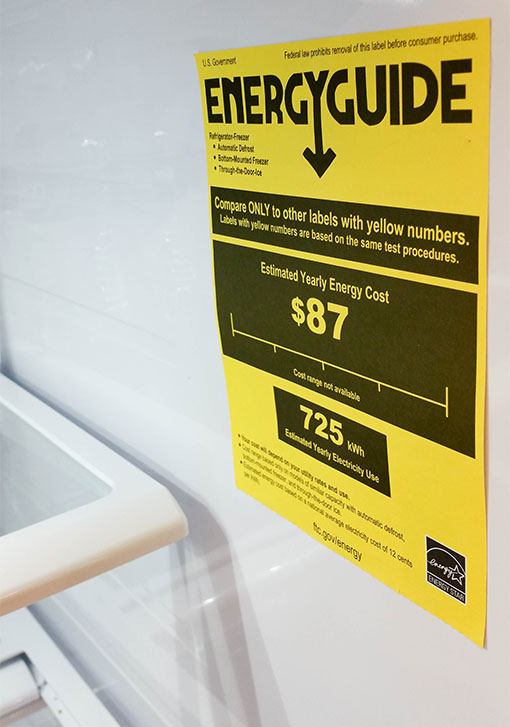

Electricity demand by refrigerators and freezers was historically met by vapor compression refrigeration technology with a single compressor, evaporator, and condenser. Such a design mixes the air between fresh and frozen food, which can lead to moisture loss, frost formation, and degraded food. With a dual-evaporator approach, a post-condenser valve system corrects the cooling load and increases energy efficiency, but achieving this design requires extra components and higher production costs.

In 2014, Whirlpool Corporation and DOE partnered to increase appliance efficiency. A cooperative R&D agreement allowed Whirlpool to access Oak Ridge National Laboratory’s modeling tools and facilities. The agreement not only supported the design, validation, and prototyping of new technology but also allowed Whirlpool to retain ownership of the intellectual property. The collaborative team demonstrated an advanced refrigerator design with more than 50% energy reduction per unit volume and a cost increase of less than $100.

“Whirlpool’s dual-evaporator technology was enabled by the need to meet higher efficiency standards requirements,” said Antonio Bouza, co-author. “This, in turn, motivated other companies to develop similar systems and invest in R&D in refrigerator components that improve efficiency while reducing complexity and cost.”

Fuel Cells for Forklifts: A Niche Market Proven With Large-Scale Demonstrations

Forklifts and other material handling equipment have historically been powered by gasoline, propane, or diesel-fueled engines for outdoor operations and lead acid batteries for indoor applications.

Unlike traditional power technologies, hydrogen fuel cells do not emit harmful air pollutants or carbon dioxide and do not have performance issues in cold environments. Warehouses are a sensible first market for this technology, as they need only one refueling location rather than the large network automotive applications would require.

The American Recovery and Reinvestment Act of 2009 funded demonstration of large-scale fuel cell material handling equipment. With the funding, DOE deployed hundreds of fuel-cell-powered lift trucks and advanced fueling infrastructure, data collection and analysis, and operator training. The U.S. Department of Defense also deployed 100 fuel-cell-powered lift trucks at three centers and an Army base. Throughout the 2010s, follow-on work supported the integration of 40,000 units of material handling equipment.

Ultimately, fuel cells demonstrated energy density, fast refueling, and fuel storage capacities that exceeded the performance of some of their contemporary alternative technologies—and the opening of the material handling equipment market to new innovations spawned further electrification of the equipment as well as industry interest in cleaner technologies.

The four case studies analyzed by experts at JISEA, NREL, and DOE highlight how a good balance of technology, R&D, and public-private partnership—along with regulatory and market force alignment and the right timing—can lead to successful first commercialization of clean energy technologies.

Read more about these studies in the full Frontiers in Energy Research article.

Last Updated May 28, 2025