NREL's Gallium Oxide Power Module Represents Innovation on Nearly Every Front

Some careers are sparked by dreams of greatness; others by a desire for achievement or prestige. But for Faisal Khan, chief researcher of power electronics at the National Renewable Energy Laboratory (NREL), pursuing a career in renewable energy was personal.

Khan grew up in Dhaka, the capital of Bangladesh and one of the most densely populated cities in the world. At the same time that his family battled air pollution from cars and two-stroke motorbikes, he also saw them struggle with power blackouts from the country’s failing electrical grid.

The power quality became so bad that, in 10th grade, Khan, along with several members of his local science club, taught themselves to build UPS—Uninterruptible Power Supplies—so their families would have backup power during blackouts.

That motivation has carried him through a career spanning academia, independent research, product development, multiple patents and records of invention, and finally a role as chief researcher of power electronics at the only U.S. national laboratory 100% focused on renewable energy: the Department of Energy's NREL. Now, in addition to his other work, Khan is leading a transformational project at the laboratory to revolutionize the power electronics systems within electric vehicles (EVs) and for high-power, high-voltage, industrial-scale power conversion.

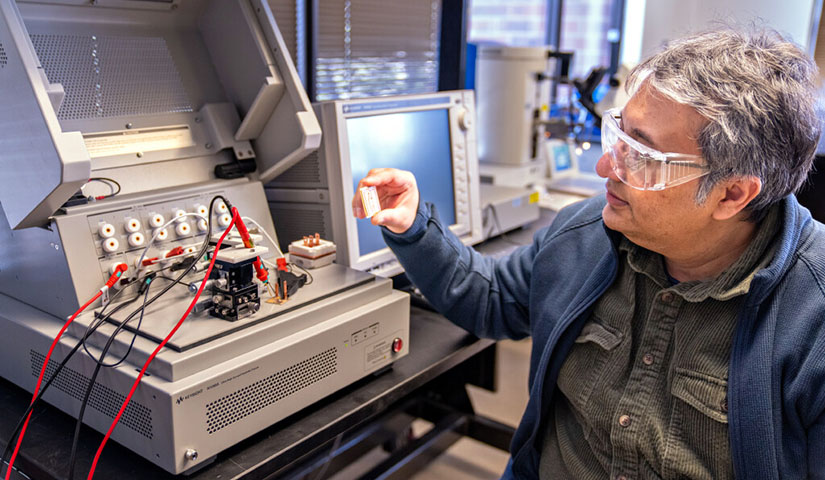

The project focuses on an ultrawide-bandgap material called gallium oxide, a cutting-edge power module design, and the project’s potential to transform power conversion systems.

Khan leads efforts on one of the laboratory’s most innovative programs: a transformational Laboratory Directed Research and Development project that harnesses NREL’s unique capacity to radically transform energy systems.

The project spans three different NREL research centers: the Center for Integrated Mobility Sciences, of which Khan is a part; the Materials Science Center; and the Power Systems Engineering Center. The team’s goal is to make NREL a one-stop shop capable of fabricating a new gallium oxide power module with built-in intelligence and an advanced cooling system.

The power module, Khan explained, works like a Lego block: Once dropped into an electric vehicle, like a car or even an airplane, it uses gallium oxide to convert battery voltage (in direct-current form) into the three-phase alternating current necessary to power the propulsion motor.

That is standard practice—most EVs use power modules to charge and convert battery power to run the motor and change speeds. But the NREL design is absolutely unique.

In general, power modules require a small amount of power to run, and normally, they are linked to high-voltage systems with cables or wires. Khan led the NREL team to design a power module that sources its power completely wirelessly. Because it requires no special wiring, the device is compatible with a wider range of electric vehicles.

What's more, the NREL design will be far more rugged than commercially available power modules. Thanks to the special characteristics of gallium oxide, a powerful, highly robust semiconductor material, the device will be capable of withstanding the high temperatures generated by the switching operations inside the power converter.

The team is even working to make the device “smart”: It will come with a block that can wirelessly monitor the module’s state of health and predict component failure before it occurs, helping to make EVs more reliable than ever before.

Power Conversion at Industrial Scale

The power module Khan’s team is developing has been designed to be fabrication friendly: Khan estimates that an entire traction inverter can be built in about 30 minutes, thanks to its wireless control and monitoring systems. And each of its additional features, from thermal management to live-monitoring the system’s state of health, are meant to make the power conversion system attractive to industry adopters.

Between its novel material use, rugged design, wireless components, advanced cooling system, and ability to predict component failure and monitor its own state of health, the device represents innovation on nearly every front.

Yet Khan, driven by curiosity and a drive to push the boundaries of what is possible, always sees potential for more.

“This is an extremely exciting project, but I am always thinking of the next step,” Khan said. “The device could be used, of course, in traction applications for electric cars, in electric airplanes, and for high-power, high-voltage, industrial-scale conversion. But we are already working on scaling this power module up for even higher-voltage applications where there are very few conventional solutions.

“That,” he mused, “would really be a breakthrough. That would be something extraordinary.”

Learn more about NREL's sustainable transportation and mobility research. And sign up for NREL's quarterly transportation and mobility research newsletter, Sustainable Mobility Matters, to get the latest news.

Last Updated May 28, 2025