Photovoltaic Toxicity and Waste Concerns Are Overblown, Slowing Decarbonization--NREL Researchers Are Setting the Record Straight

PV Modules Drastically Reduce End-of-Life Material and Toxicity Hazards Compared to Other Sources of Waste

Photovoltaic (PV) electricity generation is essential for achieving decarbonization targets and mitigating climate change. Current forecasts call for more than 75 terawatts of PV to be deployed globally by 2050—a more than tenfold increase in the current manufacturing and deployment rate in less than 15 years.

However, this ramp-up in deployment has led to growing concerns about PV waste and toxicity. Communities, government agencies, and policymakers worry about the quantity of waste that could arise from decommissioning PV modules, as well as their potential to leach toxic metals.

In an article in Nature Physics, National Renewable Energy Laboratory (NREL) researchers Heather Mirletz, Silvana Ovaitt, Taylor Curtis, and Teresa Barnes, along with coauthor Henry Hieslmair of DNV, debunk these concerns.

"One of the big takeaways from our work is that communities, government agencies, and the public as a whole—including policymakers—are operating under outdated assumptions and misconceptions about PV," said Taylor Curtis, a researcher in the Markets and Policy Group in NREL's Strategic Energy Analysis Center. "And that's resulting in delays in decarbonization."

PV Waste Is Not a Reason To Slow Deployment

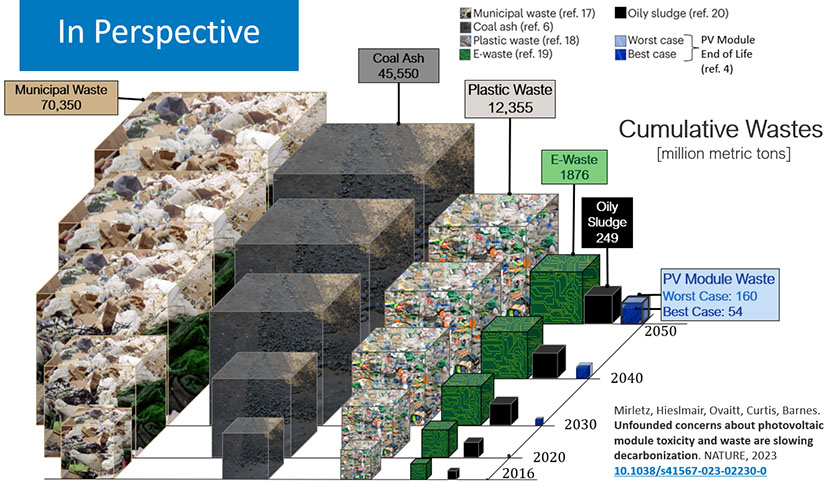

One common misconception is that the amount of PV waste the world will see in the coming years will be massive. However, the authors' projections estimate that cumulative PV module waste by 2050 will be between 54 million and 160 million metric tons (the latter being a highly unlikely, worst-case-scenario estimate). These amounts are dwarfed by other types of waste, including municipal waste, coal ash, plastic waste, e-waste, and oily sludge.

"PV waste is very manageable and should not delay deployment—it's not a reason to slow down," said Teresa Barnes, director of the Durable Module Materials (DuraMAT) Consortium. "We will have less waste from PV than we do from traditional fossil sources of electricity, and it's less toxic than some of the other fossil energy waste. These end-of-life PV materials are something we can handle."

"We aren't looking at a 'tsunami' of waste, as other sources have claimed," said Heather Mirletz, a Ph.D. candidate at NREL and Colorado School of Mines. "It is absolutely manageable within our capabilities. The fear of end-of-life materials shouldn't slow down deployment."

Common PV Toxicity Concerns Are Based on Outdated Data

Another key concern that is slowing deployment is PV toxicity. Fears about toxicity are in part driven by lists on several U.S. state health department websites that claim that toxins such as arsenic, gallium, and hexavalent chromium may be present in PV modules.

"Most of these toxic elements are simply not present in modern PV modules," Barnes said. "These lists are outdated and misleading; in many cases, they are based on research papers from the 1970s and highly specialized PV technologies that are used in outer space."

In reality, the vast majority of today's PV modules are either crystalline silicon or cadmium telluride (97% and 3% of the 2022 market share, respectively). Crystalline silicon PV modules are 77% glass, 10% aluminum, 3% silicon, and 9% polymers, with less than 1% copper, silver, and tin, and less than 0.1% lead. Cadmium telluride (CdTe) modules are 80%–85% glass, 11%–14% aluminum, 2%–4% polymers, less than 0.4% copper, and less than 0.1% tellurium and cadmium. (All percentages are by weight.)

"The two materials of concern are the trace amounts of lead in the solder of crystalline silicon panels, which represent a very small percentage by weight—less than 0.1%—and the cadmium in CdTe, which, in some of the newer modules, is as low as .008%," Curtis said.

The International Energy Agency has confirmed that these are the only potential human health and environmental concerns in commercially produced PV modules.

"There's a lack of accessible, well-communicated information out there, which makes it difficult to understand the real risks," Mirletz said. "It's crucial to put the information we have into context. The reality is that the levels of these toxic metals are very, very low. If we thought that solar panels would cause active harm to the environment, we wouldn't have them on our own roofs."

The authors found that these concerns about PV end-of-life materials and toxicity are slowing down decarbonization at a critical juncture in the energy transition.

"In some communities, developers are being asked to prove that PV panels are not hazardous prior to getting the permits they need for development," Curtis explained. "At the local level, we've seen bans and moratoriums on PV development, as well as CdTe technology bans that are based on misconceptions about cadmium and tellurium. We've counted 16 counties across six states that have implemented such policies, and their reasoning is at least in part due to toxicity concerns. This makes it critical for us to address these concerns with objective data."

Circularity Is Key to the Future of PV

In addition to combatting waste and toxicity concerns with data, the solar industry is proactively mitigating PV toxicity and end-of-life materials by investing in circular strategies and sustainable development practices. For example, the PV industry is actively working on designing more efficient, longer-lasting modules, which will lead to less material demand and reduced waste. To facilitate this research, NREL will be hosting a PV Circularity Workshop on March 3–6, 2024.

"Circular economy options can strengthen our PV manufacturing, deployment, reuse, and recycling industries. But exploring the system dynamics, materials, energy, and carbon viability of our different options in a decarbonized future is very important for empowering the right decision-making, policies, and research," said Silvana Ovaitt, a researcher in NREL's Performance and Reliability Group. "We hope that the PV Circularity Workshop, as well as all our future work, will further help move the dialogue beyond addressing misinformation—and even beyond the low-hanging fruit of recycling as the default circularity path—to more actionable sustainability paths and systems through longer PV life spans."

Read the full article.

Last Updated May 28, 2025