Biorefinery Model Points to Better Method at Producing Co-Products

A next-generation biorefinery model holds the potential to produce biofuels and chemicals through a process that researchers say has proven to be more efficient in converting plant biomass.

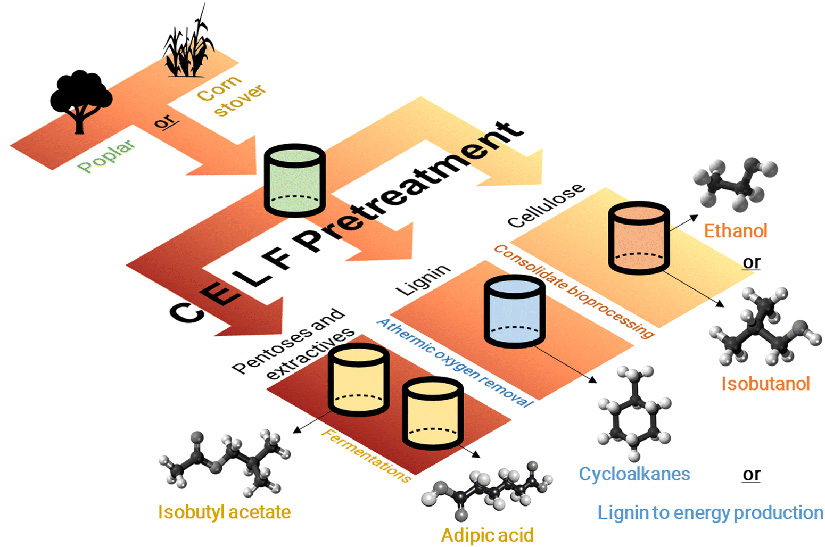

The co-solvent enhanced lignocellulosic fractionation pretreatment process, or CELF, provides a use for the lignin portion of biomass. Because lignin provides rigidity to a plant cell wall, breaking it down can be difficult. Harsh pretreatment steps can render the lignin useless as a feedstock, leaving it suitable only for burning for process heat.

CELF, however, allows for lignin and other parts of biomass to be deconstructed and fractionated to yield a diverse product portfolio including sustainable aviation fuel. The process also allows biorefineries to maximize biomass utilization by the high recovery of sugars and lignin. The findings are spelled out in a new paper published in Energy & Environmental Science, “Economics and global warming potential of a commercial-scale delignifying biorefinery based on co-solvent enhanced lignocellulosic fractionation to produce alcohols, sustainable aviation fuels, and co-products from biomass.”

The study marks the first effort toward a comprehensive understanding of a full-scale multiproduct biorefinery using CELF pretreatment of poplar wood and corn stover. Existing biorefineries typically focus on the production of one product at a time.

“Future biorefineries will have to add value to multiple biomass fractions at the same time to increase their economic competitiveness,” said Bruno Klein, a research engineer in the Economic Sustainability & Market Analysis group at the National Renewable Energy Laboratory (NREL) and lead author of the paper. “CELF-based biorefineries carry out an upfront fractionation of lignocellulosic biomass, thus allowing for the simultaneous production of various products, each from a major biomass component.”

The initial efforts to produce biofuel years ago relied on food crops such as corn and sugarcane, breaking those down into sugar syrups that can then be converted into ethanol. Subsequent research moved away from food crops in favor of forestry and agricultural byproducts such as wood residues or corn stover. Biorefineries use different technologies to convert biomass into each intermediate, so the desired product—fuels or specialty chemicals, for example—determines its design.

The researchers pointed to advantages that come from using CELF:

- The suite of downstream conversion technologies yields alcohols, esters, carboxylic acids, and hydrocarbons as co-products from biomass.

- CELF pretreatment favors feedstocks containing more available carbon for processing (poplar has an edge over corn stover).

- Ethanol produced from CELF-derived cellulose could enable the production of sustainable aviation fuel at a break-even price as low as $3.15 per gallon of gasoline equivalent.

- All CELF biorefinery configurations offer substantial greenhouse gases emissions savings when compared to an equivalent portfolio of products obtained using conventional processes/technologies.

In addition to others from NREL, the paper was co-authored by researchers at Oak Ridge National Laboratory and the University of California, Riverside, where CELF was developed. The Center for Bioenergy Innovation, a U.S. Department of Energy Bioenergy Research Center supported by the Office of Biological and Environmental Research in the Office of Science, funded the research.

Last Updated May 28, 2025