Cementing the Path to Carbon Neutrality

NREL Brings Together Experts From Across the Country for Annual Cement and Concrete Decarbonization Meeting

The National Renewable Energy Laboratory's (NREL's) South Table Mountain Campus is a scenic, scientific destination nestled at the base of the Front Range of the Rocky Mountains. Home to unique laboratory capabilities and industry-leading experts, it was also the location of NREL's second annual Cement and Concrete Decarbonization Meeting on July 30 and 31, 2024.

While coordinating a group of over 100 professionals in one location was no small feat, an atmosphere of collegiality and excitement was palpable throughout the event as attendees considered new ways to improve the second most utilized resource in the world. This two-day event brought together representatives from technology startups, investment firms, academia, industry, corporate institutions, and the national laboratory system to discuss the transition from the carbon-heavy production of cement and concrete to more sustainable solutions.

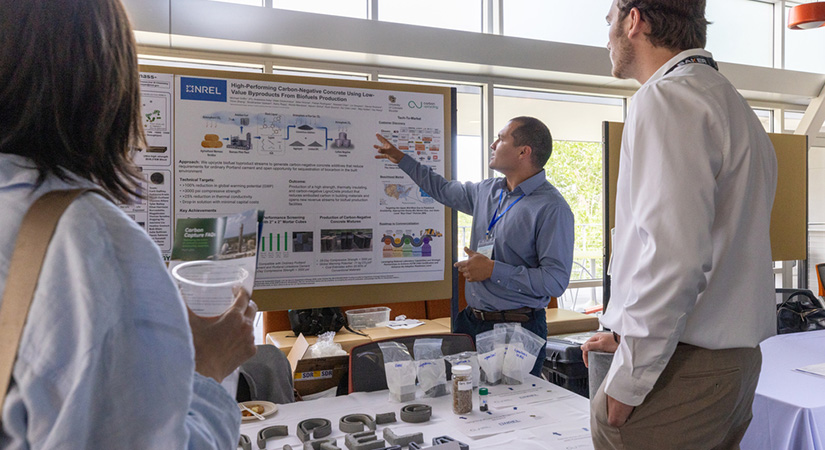

Panel discussions focused on a range of topics—major players leading demand and driving action, efforts to increase market acceptance and adoption, transparency and credibility in carbon accounting, and commercial realities that highlight emerging technologies. The meeting also featured an engaging breakout workshop session, an innovation and demonstration hall, and interactive discussions with perspectives from across the value chain. Tours of NREL's world-class Energy Systems Integration Facility and the neighboring U.S. Bureau of Reclamation's Concrete and Structural Laboratories were other highlights of the event.

The event kicked off with remarks by NREL Director and President of the Alliance for Sustainable Energy Martin Keller, who noted that decarbonizing this field is a priority to meet several of NREL's top goals.

"The challenges are huge," Keller said, "but the work you are doing in this area is incredibly important and will make a big difference in creating a clean energy future and a more sustainable and resilient industry."

Keller's remarks were followed by a welcome by Ana Aday, a materials science researcher in NREL's Building Technologies and Science Center who is also part of NREL's Advanced Manufacturing program. Aday was a key organizer for the event and has done extensive research on concrete while at NREL.

"This meeting ties into and will help inform current and future research at NREL in the low-carbon cement and concrete space," Aday said of the event. "Many of the attendees have either collaborated with NREL as industry mentors or on industry advisory committees for our projects. This event brings together all of the projects and industry members in one location to collectively share learnings and hear from industry on their needs as well."

Decarbonizing the Second Most Utilized Resource on the Planet

For the uninitiated, cement and concrete may seem like the same material, but cement is the powder that binds materials together to create concrete. In baking terms, cement would be one of the dry ingredients used to make the (concrete) cake. And though cement is only a small portion of what makes up the overall concrete mixture, it is the energy-intensive production of cement that accounts for 8% of all global CO2 emissions.

The U.S. Department of Energy's Industrial Decarbonization Roadmap identifies the U.S. cement industry as one of four pivotal paths to reduce industrial emissions through innovative American manufacturing. To align with net-zero goals, the road map outlines strategies such as waste reduction in concrete construction, continued development of new technologies, carbon capture, and use of low-carbon materials.

Cement production is notorious for its energy consumption and production of carbon emissions. The process involves heating billions of tons of materials to 1,450°C, generally achieved using coal or natural gas. Not only are there emissions associated with these high temperatures, but the chemical reaction used to make cement involves transforming limestone (calcium carbonate) into calcium-oxide compounds, which generate carbon dioxide (CO2) as a reaction byproduct.

So how does the buildings industry solve the problem of CO2 emissions from cement production and concrete use? Bringing together some of the biggest movers and shakers in the field is certainly one way to make progress. Sharing successes and roadblocks, showcasing game-changing technologies and materials, and building in plenty of time for networking and candid conversations during this annual event allows for new partnerships and ideas to form.

"Decarbonization of the cement and concrete industry is a huge challenge because of the diverse stakeholders involved across the ecosystem," Aday said. "We have heard from the industry that education, communication, and a trusted convening entity is imperative if the industry is going to successfully reduce emissions by 2050. The extensive knowledge sharing from cement producers, engineers, academics, startups, and industry trade groups demonstrates that all stakeholders are welcome at the table. Meetings like this ensure that this diverse set of stakeholders brings all their collective experiences and expertise to the table, further supporting the communication and knowledge sharing that is needed in this industry."

From Research to Reality

In many ways, NREL's campus is an apt location for a meeting on industry standards and practices for cement and concrete decarbonization. As a national laboratory, NREL takes a holistic approach to decarbonization solutions by considering and addressing the entire value chain, the circularity of industrial processes, and how all of this is interconnected.

"NREL and national labs have a unique opportunity to face the cement and concrete decarbonization challenges with a long-term vision by spending time on innovations that have a low- to mid-technology readiness level," Aday said in a recent interview. "We understand the need for private industry to maintain a return on their investments, which requires them to integrate technologies that are market ready with limited to no risk."

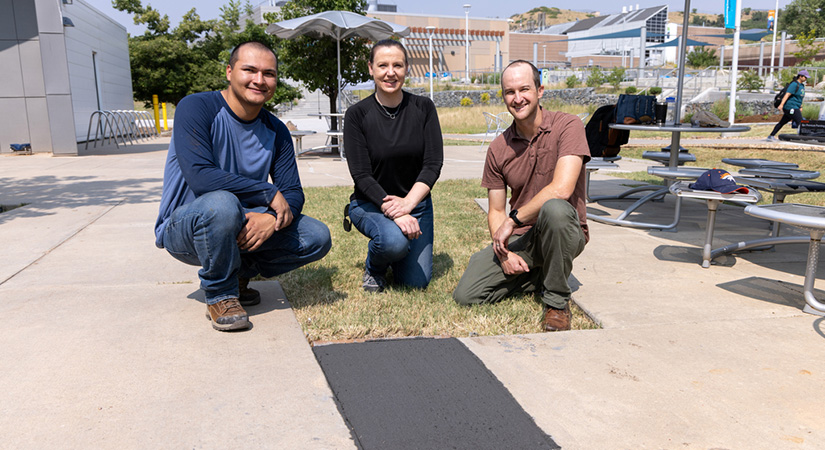

This summer, NREL showcased two of these projects on campus in the form of a new carbon-negative concrete slab and brick pavers outside of the NREL Research Support Facility and its Café. The concrete slab is part of an Advanced Research Projects Agency–Energy-funded project to develop carbon negative concrete, called LignoCrete, utilizing a new material called Activated Lignin Carbon, which reduces the amount of cement required to mix the concrete. Meanwhile, the new pavers are part of a separate project called the Biomass Upcycled in Lignin for Decarbonizing Energy-Intensive Materials (or "BUILD'EM" for short) project. Both projects serve as first steps to achieving larger goals but stand as an important proving ground that will allow researchers to test their products in a real-world setting.

"NREL has been creating solutions to decarbonize cement and concrete right here in the lab," said Achilles Karagiozis, director of NREL's Building Technologies and Science Center. "By bringing this group of constituents together on our campus, we can demonstrate this work while also hearing from diverse perspectives in the field, from investors to industry experts to other researchers and academics. Fostering these conversations allows everyone involved to continue to innovate in this space and create pathways to validate and create a scientific backbone for advances in cement and concrete decarbonization."

Learn more about buildings research at NREL.

Last Updated May 28, 2025