Manufacturing Masterminds Q&A With Jibo Sanyal: The Nature Lover Who Sees Our Planet From a Bird's-Eye View

Jibonananda Sanyal (who goes by Jibo) grew up in Shillong, India, a city located more than 5,000 feet above sea level. With houses tucked into lush hillsides, like perky poppies in a green bouquet, Shillong looks more like a mythical paradise akin to the magical elvish realm of Rivendell from "The Lord of the Rings" (both cities boast impressively tall waterfalls).

In Shillong, Jibo lived entangled with nature. But that wild growth didn't obstruct his bird's-eye view.

Today, Jibo is the group manager for the National Renewable Energy Laboratory's (NREL's) Hybrid Energy Systems team. From his first job, Jibo's superpower was to see the world and its many systems—including buildings, manufacturing facilities, energy grids, cities, and even traffic—from, well, 5,000 feet up.

At NREL, his sweeping sight is focused on clean energy, specifically how to seamlessly connect our many renewable energy technologies—like solar panels, wind turbines, hydropower facilities, batteries, and more—so they can give us what we need: consistent, reliable electricity and a solution to slow climate change. Only then can we protect the planet and places like Shillong or Jibo's new mile-high home, Denver, Colorado, from losing their splendor.

“Our thesis is pretty simple,” Jibo said. “Just one technology is not going to cut it, and we don't have 15, 20, or 30 years to prove out certain technologies before we use them. We simply don't have that much time for a clean energy transition.”

To beat time, Jibo predicts the future—except his tool isn't a crystal ball or soggy tea leaves; it's a supercomputer. Inside that powerful system, he maps out power systems (and more), analyzing, for example, how power outages impact a city in real time, building simulations to tinker with and improve a city's current energy systems, or bombarding virtual replicas of hybrid renewable energy systems with cold snaps, superstorms, and other challenges to make sure they can rebound and then expand to serve communities, cities, and entire regions.

“All these systems are inherently codependent, all for our comfort, benefit, and livelihood,” Jibo said. “There's this glue that keeps interdependent things functioning, and that's energy.”

In the latest Manufacturing Masterminds Q&A, Jibo shares why a prosthesis changed how he sees himself and how clean energy could help manufacturing facilities do far more than just reduce their emissions.

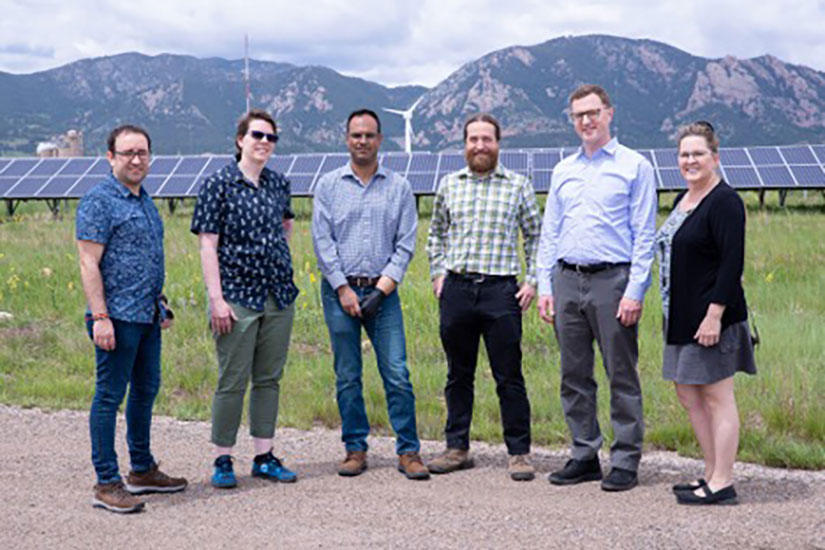

As the group manager for NREL's Hybrid Energy Systems team, Jibo Sanyal (third from left), studies how future systems—including the power grid, buildings, and cities—can seamlessly integrate to provide communities with the steady power they need. Photo by Joe DelNero, NREL

Did you always know you'd end up in computer science?

Growing up in Shillong, I was close to nature. A big part of me wanted to do something with geography or nature—things like that. But it was safer to go into computing and the hard sciences. It just made more sense.

You could have done almost anything with computing. How did you end up building a career that, in some ways, connects to both your childhood loves, geography and nature?

When I was getting my Ph.D. in the United States, I worked on projects for NASA, the National Aeronautics and Space Administration, and NOAA, the National Oceanic and Atmospheric Administration, that had to do with the Earth and sun systems. The NOAA project had to do with extreme weather events and floods and how we analyze output from weather models. There was that connection back to geography or systems that are geospatial. Since then, I've been connecting the more applied sciences to geospatial dynamics.

First, I worked at the Oak Ridge National Laboratory (ORNL) where energy was our bread and butter. I worked with buildings, controls, traffic flow, and the electric grid. When you're looking at these systems across a large area, there's a distinct geospatial aspect to them.

What is it about that big picture view that captivates you?

Impact is super important. At ORNL, I got into projects that had to do with situational awareness, and impact became quite important. For example, I was the technical lead on a project called Eagle-I, which is used by many agencies, including the Federal Emergency Management Agency, to provide real-time data on power outages and support emergency response. That connection to a technology's impact gives me a lot of energy.

No pun intended, right? So, how did you end up at NREL?

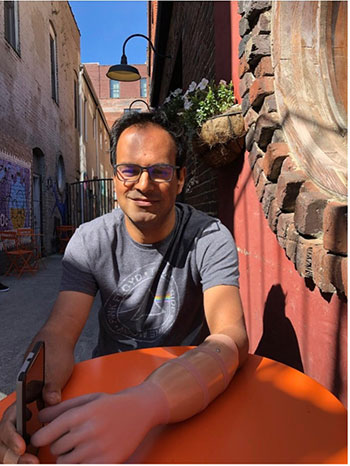

Jibo took a job at NREL after his priorities shifted (one of his top goals is to solve the climate crisis and save the planet for future generations). “If you're a curious person, the national labs are like Disneyland for science,” Jibo said. Photo from Jibo Sanyal

We need to figure out this climate crisis so there is a future for our kids. Also, as you age, your sense of mortality becomes stronger, especially if you go through certain events. I lost my mom to cancer during the COVID-19 pandemic. All these events caused my priorities to shift.

Did you face any challenges or barriers along your career path?

I am missing fingers on my left hand. I used to be a hands-in-the-pocket kind of a person. I was always decent at academics, but I was never certain about how my hand affected how I felt about myself or my opportunities—whether I didn't get the job because I wasn't smart enough or because of something else. That was always there in the back of my mind.

But I don't care about it anymore. Now, I use a medical prosthesis. And the journey to acquire one helped shape how I feel about myself and how open I am. A big part of the attribution goes to my wife, who has been a rock-solid supporter. Growing up in India, there were stares, and they would happen here too. Now, when I wear a prosthesis, people still look, but it's a different kind of stare, and it doesn't make me feel uneasy anymore.

What are you working on now that you're at NREL? Is it different from what you did at ORNL?

I grew up professionally at ORNL. Everything I know, I learned there. At NREL, I have found people have a profound belief that we have a role in saving the planet, and that is so empowering.

Here, the group I run is working on hybrid energy systems. One technology cannot enable the energy change we're after. New technologies need to integrate well and work in any condition. They also need to scale up to serve communities, cities, and regional energy systems. We are after that systems-scale validation and scale-up to make clean energy technologies economically viable.

That sounds challenging. There must be a lot of moving parts.

When you start thinking at that scale, you must look at the interdependencies between the places where you use your energy. You wake up, typically in a building. You take some means of transport to go to work and spend the rest of your day in another building or factory or vehicle. At the end of the day, maybe you pick up your kids and groceries, go to the gym, and then come back to another building, and the cycle repeats.

All these systems need energy, and they're inherently talking to each other. The more we try to optimize and save energy, the more we have to face this inherent interconnectedness. That's what we're after: How do we prove these systems out? How do we integrate these emergent, cleaner technologies together? How do we scale them up? And then how do we improve the economics so we can accelerate their adoption?

How does manufacturing fit into this bird's-eye view planning?

Jibo said he used to enjoy painting but now he mostly crafts things, like a toy engine built from a leftover salt box, with his child. He also enjoys hiking and traveling. Photo from Jibo Sanyal

Everything around us has been manufactured somewhere using energy. And industrial energy use accounts for about a third of all energy used in manufacturing. As industries consider various clean energy technologies, cost is important. Other cobenefits, like reduced waste, better work environments, fewer hazards, or no or reduced emissions, don't always make their way into their final decisions.

We're building a tool that will help quantify these nonenergy benefits. For example, if a new technology enabled your water to come out cleaner and with no waste generated, what is the value of that? Can it help make a case for investing in that technology? That's what we're working to quantify. Ultimately, we're hoping the tool will help make a better case for clean energy choices.

You're also invested in energy as it relates to future energy development, right?

It's a very critical topic. A large chunk of historical investments have been made in places where we think we'd get the most bang for the buck or where we already have data and equipment. That perpetuates the cycle of certain communities lacking technology investments. We increasingly rely on data to make energy decisions, and we need to ensure that chasm doesn't keep growing. This requires investment to catch communities up to others. This is quite critical to our energy change.

What advice would you give to a young scientist hoping to follow in your footsteps?

Follow your curiosity. And never lose sight of impact. Ask yourself, “What will your work lead to?”

Interested in building a clean energy future? Read other Q&As from NREL researchers in advanced manufacturing, and browse open positions to see what it is like to work at NREL.

This article has been updated to reflect an editorial change made after its original publication.

Last Updated May 28, 2025