Q&A With Travis Lowder: Not All Climate Crusaders Need a Technical Degree

And Some Can Love James Joyce as Much as Clean Energy

In 1993, somewhere in the hectic, lush suburbs between New York City and upstate New York, a preteen Travis Lowder was turning off the lights.

“I just remember thinking, ‘This is a big deal,’” Lowder said.

In school, Lowder was learning all about the shadowy threat of climate change, the hole in our ozone layer, acid rain, and other planetary aches. It bothered him. So, he asked his sixth grade teacher how he could help. “Make sure the lights are turned off,” his teacher told him. “Don’t waste energy.”

So that’s what Lowder did.

“Every time I turned off the light, I was very conscious that I was doing this for the planet,” Lowder said.

But eventually, flipping a light switch was not enough. He wanted to do more.

Today, Lowder is a senior project manager with the National Renewable Energy Laboratory’s (NREL’s) Accelerated Deployment and Decision Support Center. And in some ways, he still is a switch flipper—but on a grander scale. Lowder straddles the gap between energy experts and the U.S. heavy industry, which includes steel, cement, food and beverage production, and mining operations. These industries are responsible for about a quarter of the country’s total greenhouse gas emissions. But because they need energy—a lot of energy—they are a challenge to decarbonize.

“There’s a right answer to 2+2=4, but it’s a lot more complicated than that out in the real world,” Lowder said. “We’re all humans.”

The U.S. heavy industry is always looking for new science that could help their facilities produce more and consume less. But it’s still humans who decide which changes to make and when. That’s where Lowder comes in.

“There’s so much cool stuff happening across the lab, but how do you get people to adopt it?” Lowder said. “That takes sitting down at the kitchen table with people. Let’s build that trust before we can even talk about trying to get these technologies implemented.”

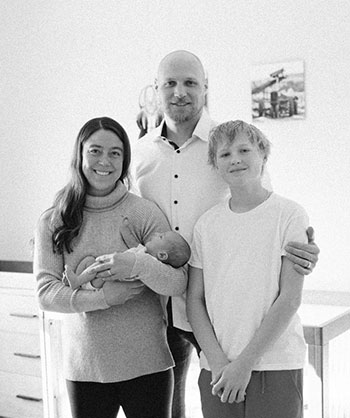

Travis Lowder, seen here with his wife and one of his sons, always thought that his lack of a technical degree would prevent him from getting a climate-change-related job. Turns out, you can love James Joyce’s "Ulysses" (and even identify with the bumbling but oh-so-human main character, Leopold Bloom) and still get a job saving the planet. Photo from Travis Lowder

In other words, Lowder works directly with partners—like the steel and mining industry, chemical companies and international foundations, and even governmental agencies—to figure out: What will it take to get you to flip the decarbonization switch?

As it turns out, Lowder shares a common challenge with the industries he supports; his path to clean energy was anything but smooth.

In the latest Manufacturing Masterminds Q&A, Lowder shares why he did not need a technical background to fight climate change (and neither do you!) and why humility might be the most crucial trait for his job. This interview has been edited for clarity and length.

Based on your dogged efforts to turn all the lights off, it seems like you were a very conscientious kid!

Both my parents are conscientious people, particularly when it comes to leaving the world better than you found it. But it’s not like my parents were trying to inculcate that in me. It just so happened that we were sympathetically similar. The apple didn’t fall too far from the tree.

I also grew up in the age when the Montreal Protocol and efforts to reduce emissions to mitigate acid rain had broad support. Climate change was being taught in primary and secondary schools. I do feel like I was a beneficiary of a certain time and place.

Lowder said his wife loves what is known as Type 3 Fun, which is, well, not fun. Lowder loves to read, but he also goes backcountry skiing, hiking, camping, and backpacking with his wife, who is a die-hard mountaineer. “I’m afraid of heights,” Lowder said, “so I sit some of that stuff out.” Photo from Travis Lowder, NREL

You mentioned that you always knew you wanted your career to be climate related. Did you have to overcome any barriers to make that happen?

Yes, I don’t have any technical degrees. I’m not a scientist. I started more on the activist side of things. I have a liberal arts bachelor’s and a political-science-oriented graduate degree. I had to figure out how to leverage these to succeed in the renewable energy job market when it was much smaller than it is today.

So, what is your background?

I was an English literature major. I considered going into journalism, but I wanted to get my hands dirty with projects. I told one of my graduate school professors that I felt like I was at a disadvantage when I was job hunting because I didn’t have a technical degree. But he told me that English lit imparted its own competitive advantages: the ability to tell stories and relate to people on a human level. He said, “You’ve got to lean into that.” And he was totally right. His advice helped me carve out a niche for myself.

What is that niche?

The space I inhabit straddles technical aspects, client management, project execution, and strategy. I strive to support NREL’s technical people; however, I can also get the great work they do to market.

So, how did you end up at NREL?

I started at NREL in solar finance. And I left in 2017 to go to a solar developer and double down on that. But when I came back to NREL in 2018, I wanted to learn new things. Mark Ruth, NREL’s laboratory program manager of analysis coordination, and Sridhar Seetharaman, a joint faculty appointment from Arizona State University, gave me a chance to work on a green steel project, which catapulted me off in a new direction. I’m very grateful that they believed I could do that even when I didn’t have domain-relevant background.

Now, you’re heavily involved in industrial decarbonization projects, like green steel. What does a typical day look like for you?

Right now, I am a business development lead and project manager, so I split my day into two things. In partnership development, I think about how we engage partners, expand our impact, and ensure we are giving companies what they need to meet their industrial decarbonization or renewables goals. Basically, I try to match our lab’s capabilities to the problems that exist out there. And, of course, in this line of work, you have to pick up the phone.

In project management, I coordinate teams to ensure we’re delivering the highest-value product for our partners. This includes a lot of mundane stuff, like monitoring budgets, keeping track of timelines and deliverables, and unsticking things when they’re stuck. But it also offers the opportunity to think and act strategically, which is what I really love about my job.

Lowder, seen here with his wife, 3-month-old, and 13-year-old, thinks we do not have the luxury to wait generations to come up with climate change solutions. “The biggest challenge is accelerating decarbonization to avoid the worst effects of climate change. That’s what I want to do with my life,” Lowder said. Photo from Travis Lowder, NREL

Have there been any especially surprising challenges when working with partners?

When I started engaging the mining industry, I came at their challenges with a straight up, “You need renewables, and I know how to do that.” But their challenges were a lot more sophisticated than I knew. Any mining company could go procure a solar or wind plant with battery storage to support their operations, so what was NREL’s value-add? I had to check myself a little bit and realize I didn’t have all the answers.

After some research and listening tours, we reformulated how NREL can support mining decarbonization, and we’ve had some success in engaging partners. For example, we’ve collaborated with major producers in the iron and steel sector to model economics and emissions for various decarbonization pathways, worked with a mining company to develop a plan for a 100% renewable-energy-powered mining grid, and helped other companies to model heat electrification.

Humility is key when you are approaching new partners and trying to understand their situation. Humility is key, period.

What do you think heavy industry’s biggest challenges are right now?

Heterogeneity is one of the principal barriers. Solutions for iron and steel don’t really apply to food and beverage, for example. Meaningful decarbonization is impossible without a subsector approach. Process heat is the major cross-cutting solution, but even with heat, you have to tailor your technology and application to the specific subsector and even plant.

Manufacturers live and die by their processes. They need to pump out product at high volume and meet rigorous quality standards. You can’t put out products that are going to catastrophically fail or make people sick. It’s your reputation. Weaker steel, even if it’s manufactured as “green,” will lose you business and potentially much worse. And, of course, you need to find the right solution while minding an insanely tight payback period and overcoming institutional inertia. Easy.

Can NREL help industry identify solutions?

NREL can and does support a lot of this work—like technology development, materials research, separations, economic analysis, life cycle emissions, demonstration, and grid integration—as well as the decision-making that leads to adoption. The problem set is quite wicked and the solution space diverse, but NREL is a strong partner for companies on decarbonization journeys.

Are you optimistic industry can reach their decarbonization goals?

We don't have the luxury of living through generations to make these changes. So, the biggest challenge is accelerating decarbonization to avoid the worst effects of climate change. That’s what I want to do with my life. I’m 41 years old. Maybe I’m already halfway done with my career and my life. For the rest of my working years, I want to focus on getting to the solution faster.

What advice would you give to someone who wants to get into a climate-related career but might not have a technical background?

It’s a fantastic time to get into climate tech, however you want to do it. There are so many opportunities. You could get into R&D, develop renewable projects, join a technology startup, build software, design alternative proteins, get into the policy or regulatory game, or do marketing or communications. Know what you do best, and then go out and find a company to match. Lean into your uniqueness.

Interested in building a clean energy future? Read other Q&As from NREL researchers in advanced manufacturing, and browse open positions to see what it is like to work at NREL.

And check out our Work With Us page to learn how you can collaborate with our experts and help forge a clean energy future.

Last Updated May 28, 2025