Winners of Second Phase of Wind Prize Bring Floating Offshore Wind Energy Closer to Fruition

Newly Named Finalists in FLoating Offshore Wind ReadINess (FLOWIN) Prize Address Key Obstacles to Deployment

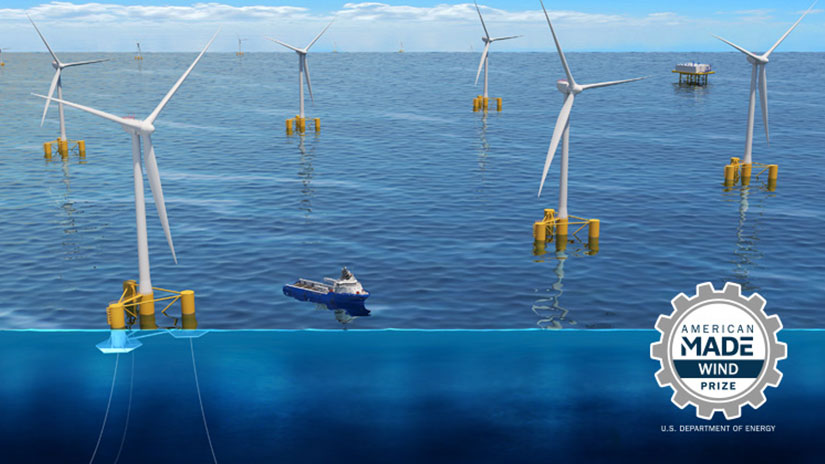

The U.S. Department of Energy just named the finalists in the three-phase, $5.75 million

FLOWIN Prize, designed to accelerate the market readiness of U.S. floating offshore

wind energy technologies. Graphic by Besiki Kazaishvili, NREL

Floating offshore wind energy has huge energy potential—2.8 terawatts in the United States, to be exact. That is more than double current U.S. electricity consumption. The White House aims to begin tapping that potential with its current goal of deploying 15 gigawatts of floating offshore wind capacity by 2035.

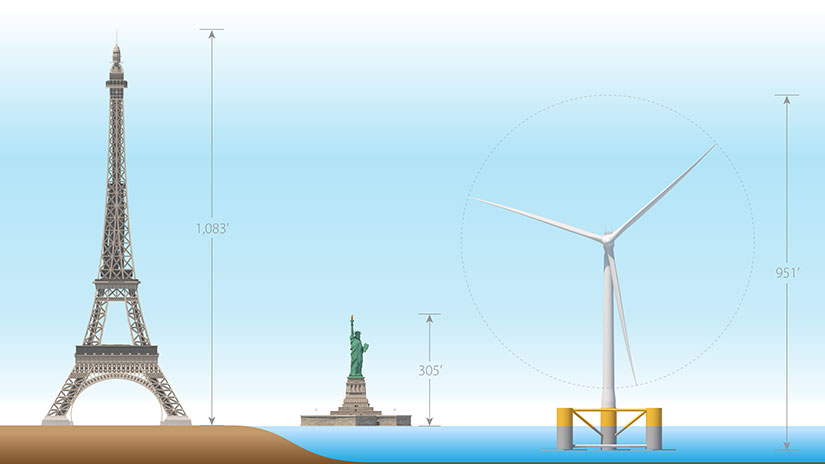

In order to meet that goal, developers will need large turbines—perhaps the largest manmade structures ever built—that can float over high-wind areas of the ocean that are too deep for today’s fixed bottom offshore wind turbines.

But bringing together the design, manufacture, supply chain, and transportation components required to deploy these sizable floating offshore wind structures may be one of the biggest challenges in the clean energy transition. That challenge is exactly what the competitors in the American-Made FLoating Offshore Wind ReadINess (FLOWIN) Prize are tackling.

The U.S. Department of Energy (DOE) has just announced the winners of Phase Two of the prize, narrowing the field to five competitors with innovative ideas for streamlining the deployment of floating offshore wind energy. Each winning team was awarded a cash prize of $450,000 and a $100,000 voucher that can be used for technical support at a DOE national laboratory as they continue to refine their designs.

The FLOWIN Prize, which is administered by the National Renewable Energy Laboratory (NREL), was designed to inspire solutions to some of the biggest supply chain and execution challenges faced by offshore wind energy in support of the government’s interagency Floating Offshore Wind Shot. Competing teams began with a concept for a floating offshore wind energy substructure; in the last phase, they worked to develop a pathway to produce and assemble the structure.

“These teams have already come up with some great, technologically ready designs for offshore wind components,” said Amy Robertson, NREL’s offshore wind group manager and FLOWIN Prize technical lead. “Now their task will be to figure out how to get their designs up and running in a specific location so we can begin deployment of the first floating offshore wind developments in the United States.”

Meet the Finalists

The following teams made the most progress in developing a plan for mass production and assembly of floating offshore wind energy platforms—they are eligible to compete in Phase Three of the prize:

- FloatHOME (Emeryville, California) — FloatHOME’s triangular platform, WindFloat, now in its fourth generation, provides deep-water stability through unique design features, including a damping system to absorb wave excitation movement. This platform has been fully modularized to enable differing execution plan options, allowing for streamlined manufacturing and adaptable installation.

- PelaStar (Seattle, Washington) — PelaStar’s floating platform is a lightweight tension-leg platform design that minimizes environmental impacts while maintaining cost savings as well as manufacturing and installation flexibility.

- Technip Energies (Houston, Texas) — Technip Energies’ INO15 design is a semisubmersible, three-column floating platform. This design can be assembled at ports at low cost and is robust enough to withstand harsh operating environments.

- Tetra Triple-One (Boston, Massachusetts) — The Tetra Triple-One floating platform uses a building-block arrangement, which involves fully producing the parts needed in an industrialized manufacturing environment and then transporting them to the assembly site. This makes portside construction possible for a range of platform configurations, turbine sizes, and site conditions.

- WHEEL U.S. (Coral Gables, Florida) — Incorporating tanks for buoyancy and balance, the ultrastable WHEEL floating platform design can temporarily act as a barge platform, allowing it to be assembled with the wind turbine near shore and towed to sea. It is compact in size to reduce both costs and carbon footprint.

These teams will now move on to the final prize phase, during which they will complete location-specific implementation pathways for domestic manufacture and deployment of their floating offshore wind energy technologies. At the end of Phase Three, up to three winners will receive a $900,000 cash prize.

The FLOWIN Prize is administered by NREL in partnership with the Oceantic Network on behalf of the U.S. Department of Energy’s Wind Energy Technologies Office in support of the interagency Floating Offshore Wind Shot.

For more information, follow the FLOWIN Prize on HeroX, explore NREL's research and development in offshore wind energy, and subscribe to the laboratory's wind energy newsletter to get news like this in your inbox each month.