With Great Power Comes Great Possibility

Meet Three Teams Competing To Build Better Power Lines and Conductors To Supercharge Our Clean Energy Future

Power lines—those high-flying cables that transmit electricity all over the country—are far from invisible. They sweep along roads, cut through yards to deliver energy to homes, and transmit power from sunny solar farms and blustery wind farms back to rural and urban communities alike.

These cables—and the thinner wires that power our computers, cars, heaters, and more—may be commonplace. And yet most people, including policymakers and even environmentalists, did not see these electron highways as a big part of our clean energy transition—or, at least, not until recently.

Now, studies show that if the United States transitions to the advanced conductors that are commercially available, that shift could save American consumers at least $140 billion over a decade. The change could also prevent 2.4 billion tons of carbon emissions over the same time period (that is about as much as Russia or Brazil emit in one year).

That is huge. But we can save even more.

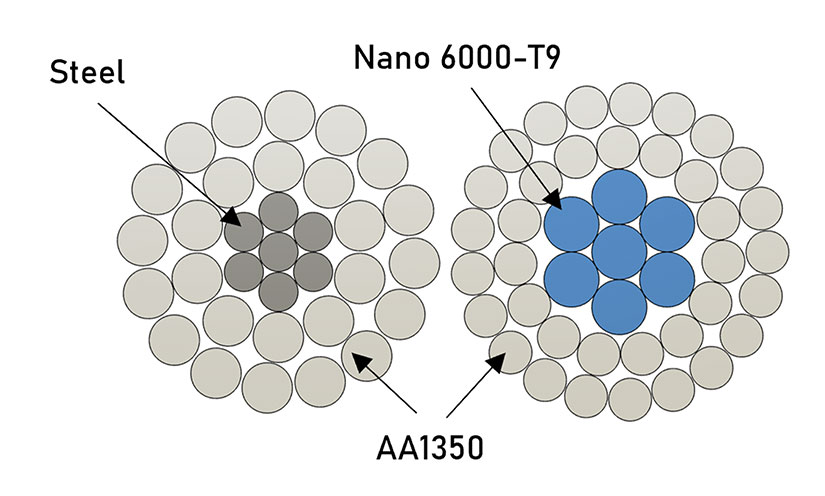

Most power lines are conductor systems or mashups of multiple metals. Today’s systems are typically made with a highly pure form of aluminum wrapped around a far less conductive but stronger core (usually steel). And almost all of today’s power line systems are based on a patent from 1908 and are sorely in need of an upgrade so they can carry more electricity.

In short, our electron highways need an extra lane. And if researchers can create more efficient, cost-effective, stronger conductors, they could get one.

Enhanced conductor systems could deliver that. These conductor upgrades could help the country save energy (because less would get lost along the way) and infrastructure costs. For example, with better conductor systems, we might not need as many power lines. And that means, the United States could avoid having to triple the number of power lines to decarbonize the country’s power grid.

To accelerate the deployment of these improved conductor systems, the U.S. Department of Energy’s Advanced Materials and Manufacturing Technologies Office (AMMTO) opened Stage 2 of the Conductivity-enhanced materials for Affordable, Breakthrough Leapfrog Electric and thermal applications (CABLE) Conductor Manufacturing Prize to teams working on this challenge. The $4.8 million CABLE Prize competition supports teams of researchers and inventors who develop and manufacture either new materials that can conduct electricity better than the traditional aluminum or new conductor systems that perform better than traditional power lines and other energy infrastructure.

In April 2023, seven CABLE Prize teams won Stage 2 for their inventions. Three of those seven fit under the prize’s Beat a Conductor System category (and two are focused specifically on creating advanced conductors for power lines).

We talked to all three to hear how they plan to build better conductor systems—or even superconductors—to supercharge transmission lines, wind turbines, MRI machines, electric motors, airplanes, and more.

NanoAL Lightning

“I see it as a whole new tool in the conductor designer’s toolbox.”

Team Name: NanoAL Lightning

Title: Ultra-High Strength/Highly Conductive Al Alloys

Institution and Location: NanoAL LLC (Ashland, Massachusetts)

Slogan: “High strength, highly conductive aluminum wire”

Josh Dorn and NanoAL Lightning are trying to solve a Goldilocks problem.

Most of today’s transmission lines are built from aluminum wrapped around a steel core. That strong interior protects these lines from sagging in high winds, heavy snows, or simply the passage of time, but it can also make the entire line less efficient. Because steel is not an ideal conductor (it is only 10% as conductive as aluminum), these standard cables do not transfer electricity as well as they could.

Steel is strong but not conductive; traditional aluminum is conductive but weak.

So, how do you make a cable that is just right, both strong and more conductive?

Dorn, a project manager and materials engineer at NanoAL LLC, is building a potential solution. For the CABLE Prize, he and his team worked on a new kind of aluminum alloy that is 60% stronger than its closest competitor. It is also 700% more conductive (and 19% stronger) than those traditional steel cores that it is set to replace. Although their new material is slightly less conductive (about 8% lower than the most comparable aluminum alloy), it could increase the overall conductivity of overhead cables by 19% by eliminating steel.

“Steel is not a very good conductor itself, so there's basically deadweight there that's not increasing your conductivity,” Dorn said. “We saw an opportunity but didn't have the resources to really make it work."

Thanks to Stage 1 and Stage 2, Dorn and the NanoAL Lightning team had the resources and platform to refine their idea. Now, the team will forgo the final stage of the prize and, instead, start to manufacture their material, which could provide an affordable way to carry more electricity from power plants to hospitals and homes.

As the country builds more wind and solar power plants—which are often constructed in remote locations where the winds blow hardest and the sun shines brightest—the country will need more transmission lines to shepherd all that electricity where it needs to go.

And, because the United States will need millions of miles of cables to build a carbon-free grid, we need both efficient and affordable cables. That is why Dorn’s team is making sure they can manufacture their new material using an affordable process.

“In a way,” Dorn said, “I see it as a whole new tool in the conductor designer’s toolbox. Compared to the aluminum alloys used in transmission lines today, ours provides that combination of strength and conductivity that aren't available anywhere else.”

Their material could be a kind of Goldilocks alloy, a perfect balance between strength and conductivity.

The MgB2 Crewe

“They’re for the whole world.”

Team Name: The MgB2 Crewe

Title: A Sapient Choice of Cables for Wind Energy

Institution and Location: Hyper Tech Research Inc. (Columbus, Ohio)

Slogan: “Sapient choice of cable for wind energy”

If you have ever had to lie still while an MRI machine bangs out a metallic, percussive jangle, then you have been in the presence of something super: a superconductor.

Superconductors are aptly named. The material is like an electron superhighway, capable of conducting electricity without resistance, which makes it far more efficient than traditional conductors. But, just like actual superhighways, superconductors have rules of the road.

For example, those magnetic coils inside MRI machines can only operate in extreme cold (around minus 443 degrees Fahrenheit). If researchers can create superconductors that can operate in temperatures that are even slightly higher, these wire systems could become far more affordable and versatile.

And that is exactly what Matt Rindfleisch, an engineering manager at Hyper Tech Research Inc., and The MgB2 Crewe are trying to achieve. “MgB2 could compete head-to-head with the wire that's in the current MRI machines,” Rindfleisch said.

But their affordable superconductor could also power more than just expensive MRIs. Because these wires can conduct more electricity with less material, they could be used to build smaller and lighter generators for wind turbines—or even airplanes. With superconducting generators, wind turbine manufacturers could build bigger wind turbines, which are more efficient and cost-effective at turning wind into clean electricity.

“Superconductivity makes that large wind turbine system more economical,” Rindfleisch said. Even though their low-temperature superconductor still needs to be cooled to around minus 390 degrees Fahrenheit, it does not depend on expensive and increasingly rare coolants, like liquid helium (the current go-to for MRIs).

Liquid hydrogen can easily help the MgB2 Crewe achieve that necessary temperature, and it is already hundreds of times cheaper than liquid helium.

Their superconductor also makes it possible to forge wind turbine magnets without using rare and expensive permanent magnetic materials, like neodymium. Often, just one or two areas around the world control these rare materials, which can make them challenging to acquire.

“Just imagine a country says, ‘OK, we’re going to raise the price or limit the supply,’” Rindfleisch said. “It’s kind of contradictory to our efforts to electrify ourselves.”

In the third and final stage of the CABLE Prize, The MgB2 Crewe will partner with researchers at the Fermi National Accelerator Laboratory (also known as Fermilab). “We're connected by the hip,” Rindfleisch said of their Fermilab partners. “A small company like us can’t afford a scanning electron microscope for example.” Together, the teams will not only manufacture the novel superconductor, but also further explore its potential for wind turbines and more.

“Just being part of this prize is fun,” Rindfleisch said. “But these net-zero emissions initiatives are not only for the United States; they’re for the whole world.”

TS Conductor

“Electrification of everything for everyone, everywhere.”

Team Name: TS Conductor

Title: Advanced Conductor With Conductive Strength Member

Institution and Location: TS Conductor (Los Angeles, California)

Slogan: “Electricity delivered better”

Everyone likes a discount, so how about a green discount?

Today, researchers and technology developers are racing to upgrade the country’s power lines and expand its transmission system so the U.S. grid can ingest more renewable energy. But there are two big barriers that can hinder these critical changes: time and cost.

And we are running out of time.

“It’s too often a slow and expensive process,” said Jason Huang, the founder and CEO of TS Conductor (where “TS” stands for “Total Solution”). “Advanced conductors, like ours, solve both challenges.”

For the CABLE Prize, Huang and his TS Conductor team are perfecting a conductor that could speed up the transition to more advanced power lines and triple the capacity of existing transmission structures.

“Kaboom!” Huang said. “And we can do it cheaper—not only better but cheaper. That’s what we mean by ‘green discount.’ Our solution is quite simple: electricity delivered better with TS technology.”

Their conductor system, which is assembled from a carbon core and an aluminum conductor, could reduce line losses by 50% (line losses refers to the power lost between the energy source and its destination). Because the team’s conductor system is also durable and strong enough to have little (if any) sagging, it could also help keep the power grid both reliable and safe. Excessive sagging has sparked wildfires. A taut cable, designed to withstand both heat and high winds, could prevent such catastrophes.

“We worry about the reliability piece—that we need more capacity, weatherproofing, resiliency—but that affordability piece is very, very important,” Huang said. “Who’s going to carry the cost of those outdated cables? The ratepayers.”

Instead, Huang’s goal is to, as he says, “facilitate electrification of everything for everyone, everywhere."

“This is not just about making the metals more conductive but making it more functional, more effective, even higher performing,” Huang continued. “If you improve the metal conductivity by 10%, that’s a breakthrough. But for us, we are talking about 200%, 300%, or even 500% capacity increase.”

That increase could help the country accelerate its transition to clean energy. And, Huang said, speed is critical. “We have a finite window of opportunity to make a difference. There’s still a long road ahead, but with everybody's support, I think we can get there. We can make a difference.”

Learn more about the CABLE Prize challenge, and follow the teams’ progress! And find out how other CABLE Prize teams are working to build a better copper.

Last Updated May 28, 2025