MATBOX: Microstructure Analysis Toolbox

NLR developed the Microstructure Analysis Toolbox (MATBOX) to analyze electrode microstructures for lithium-ion (Li-ion) batteries and other 3D heterogeneous materials.

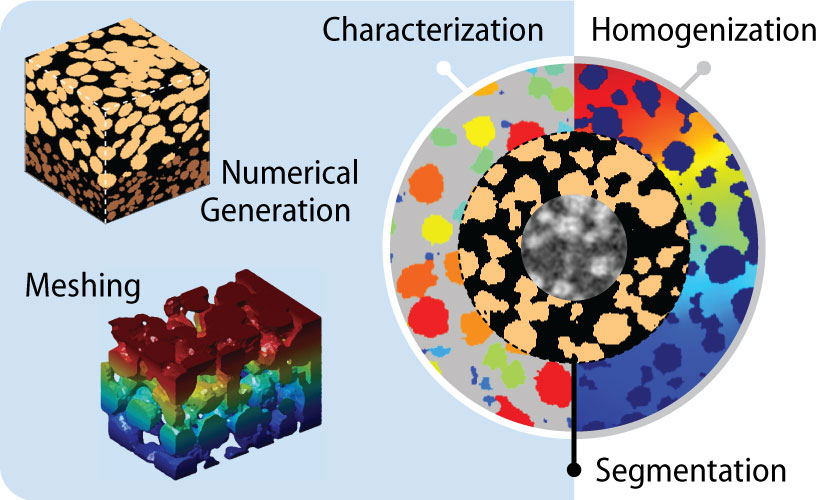

MATBOX leverages the MATLAB computing platform to perform various tasks, including microstructure numerical generation, image filtering and microstructure segmentation, microstructure characterization, 3D visualization, result correlation, and microstructure meshing.

MATBOX's main applications.

Register to Download

Access to download MATBOX will be provided after registration.

Easy-to-Use Features

MATBOX includes a graphic user interface and extensive documentation to allow users to take full advantage of the toolbox capabilities without coding. This interface ensures the tool is both user-friendly and relevant across material analysis applications. The tool is open source, allowing researchers from across industries to explore the full potential of MATBOX to guide experiments.

Streamlining Microstructure Analysis

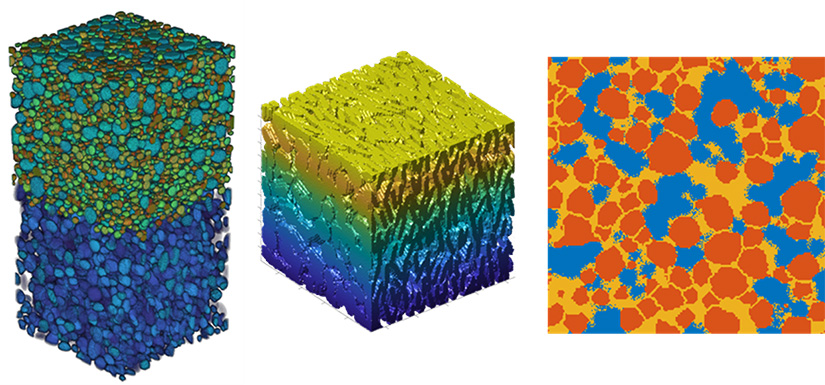

MATBOX supports users from segmentation to characterization of 3D heterogeneous volumes obtained from nanoscale imaging (such as X-ray computed tomography). Time-expensive representativity analysis is fully automated, so you can quickly assess the relevance of the imaged volumes. Calculate inputs for typical macroscale battery models—such as volume fractions, connectivity, particle size distributions, specific surface area, and tortuosity factor—but also more in-depth metrics such as geometric tortuosity, particle sphericity, and elongation.

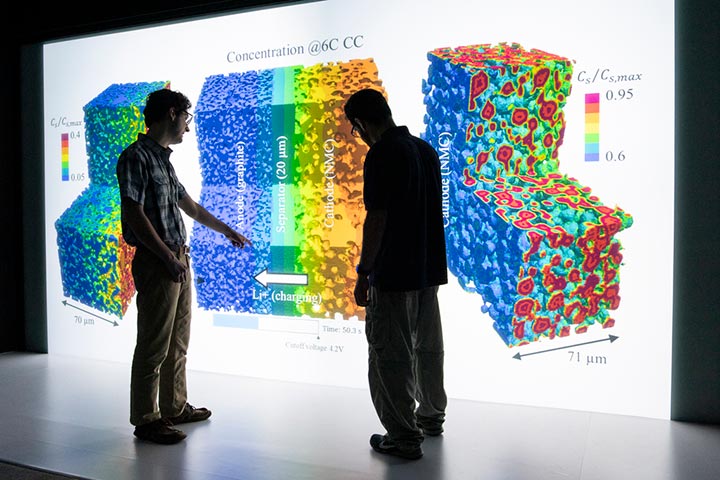

NLR researchers Francois Usseglio-Viretta (left) and Nicholas Brunhart-Lupo use the 3D Visualization Lab in the Insight Center at NLR's Energy Systems Integration Facility to discuss on simulation results performed with a domain-segregated mesh generated with MATBOX.

Generating Meshes for Full Cell Models

MATBOX provides unstructured, tetrahedron-based, meshing generation with mesh density control and smooth interface. The module allows creating meshes per phase, per group of phases with conforming interfaces, or for the full volume, respectively for homogenization calculations, domain-segregated models, and monolithic models—useful depending on your numerical framework. You only need segmented 3D TIFFs to start with.

Enable Microstructure Design Space Analysis

MATBOX provides stochastic algorithm to generate n-phase, ellipsoid-based materials, with control of volume fractions, particle size elongation, and rotation all along the electrode thickness to investigate the large design space of energy storage materials, which is useful for optimization analysis once coupled with the above-mentioned characterization and meshing modules.

Furthermore, high-energy density, low-porosity electrodes are enabled thanks to user-controlled particle overlapping and particle generation order to overcome particle density limit. Conductive carbon-black and binder additives can also be generated using two distinct methods, distance-based or energy-based, to produce realistic electrodes with all solid phases considered.

Publications

The following publications provide detailed information about the MATBOX software. Users are encouraged to cite MATBOX results based on the following guidelines.

All Results Produced With MATBOX Software

MATBOX: An Open-Source Microstructure Analysis Toolbox for Microstructure Generation, Segmentation, Characterization, Visualization, Correlation, and Meshing, SoftwareX (2022)

Results Using the Energy-Based Method To Generate Additive Phases

Secondary Phase Stochastics in Lithium-Ion Battery Electrodes, ACS Applied Material Interfaces (2018)

Results Calculating Tortuosity Factor

TauFactor: An Open-Source Application for Calculating Tortuosity Factors From Tomographic Data, SoftwareX (2016)

Results Generating Unstructured Meshes

Tetrahedral Mesh Generation From Volumetric Binary and Gray-scale Images, IEEE International Symposium on Biomedical Imaging (2009)

Requirements

MATLAB with image processing toolbox is required.

Acknowledgments

This software was authored by the National Laboratory of the Rockies, operated by Alliance for Energy Innovation LLC, for the U.S. Department of Energy under Contract No. DE-AC36-08GO28308. Funding for algorithm development was provided by the U.S. Department of Energy Vehicle Technologies Office's Computer-Aided Engineering of Batteries program under manager Brian Cunningham. Application of the algorithm for fast-charge analysis was provided by the eXtreme Fast Charge Cell Evaluation of Lithium-Ion Batteries program under manager Samuel Gillard.

Contact

Share

Last Updated Dec. 7, 2025