Non-Evaporative Drying of Porous Materials

NREL researchers and collaborators are helping the paper manufacturing industry save energy and water with a novel non-evaporative drying process using polymer chemistry.

Manufacturing paper, a massive industry in the United States and beyond, requires drying out large quantities of paper. A question of how to do that more efficiently, in terms of energy and water reuse, can mean saving up to 1.2 Quads per year and 93 million tons of CO2.

How? A team at NREL is investigating the method, thanks to a funding award from the U.S. Department of Energy's former Advanced Manufacturing Office and now its Industrial Efficiency and Decarbonization Office. The project, Non-Evaporative Drying of Porous Materials Using Thermo-Responsive Polymer/Felt Composites, received more than $2.3 million for 3 years. It is led by members of the University of Texas at Dallas and includes researchers at Auburn University and Western Michigan University.

Objectives

The project's objectives are to:

- Develop thermo-responsive polymeric materials that effectively absorb and desorb water from paper

- Integrate a continuous loop with a paper-machine for water extraction through system design and lab- and pilot-scale testing

- Quantify the energy savings through system level modeling and techno-economic analysis.

Efficient, non-evaporative drying of porous materials using thermo-responsive polymer/felt composites will be developed.

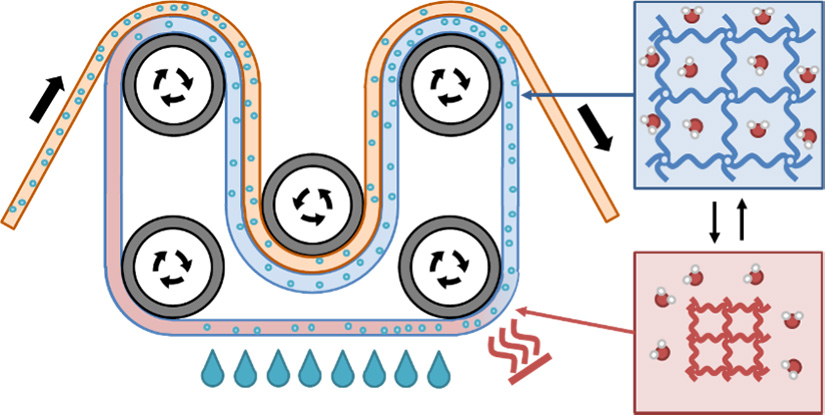

The team's new method combines chemistry, mass transfer, roll-to-roll manufacturing, industrial paper, and modeling expertise. The process incorporates a thermoresponsive belt that rotates, shuffling reams of paper across its surface. That belt, made of a polymer, changes its affinity to water with temperature and can sorb water from paper at a low temperature, and then, once the dry paper moves off the belt, the polymer undergoes a quick heated but low-energy deswelling process to remove the water it sorbed from the paper.

Patent

Super-Adsorbing Porous Thermo-Responsive Desiccants, US11819823B2 (2021)

Partnerships

The project includes researchers from:

- NREL, including: Tyler Bailey, Jon Norman, Aaryan Kapoor, Peter Osazuwa, and Alexis Medina

- University of Texas at Dallas (lead)

- Auburn University

- Western Michigan University.

Contact

Share