Closing the Loop: How NREL’s Advanced Diagnostics Enable a Circular Battery Future

As market sales of electric vehicles (EVs) continue to rise due to customer-desired attributes like improved driving performance and convenient at-home charging, they bring with them an increased demand for essential metals like cobalt, nickel, and copper.

Meeting that demand is a key challenge in the journey to widespread electrification, and battery recycling methods need to be incorporated to develop a robust EV supply chain. Offering a circular approach to sourcing EV battery materials helps support an electrified future that is both powerful and resource conscious.

In response, battery experts Ankit Verma, Paul Gasper, and Donal Finegan at the National Renewable Energy Laboratory (NREL) are teaming up with researchers from Toyota Motor Engineering & Manufacturing North America Inc. (TEMA), Oak Ridge National Laboratory, and Baker Hughes' Waygate Technologies to resolve bottlenecks facing the EV battery supply chain.

This project, led by TEMA, is funded by the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) Catalyzing Innovative Research for Circular Use of Long-lived Advanced Rechargeables (CIRCULAR) program. CIRCULAR projects aim to catalyze the transition from a linear to a circular supply chain for domestic EV batteries with solutions that extend battery life and facilitate repair and reuse to reduce waste.

"ARPA-E turns bold ideas into transformative breakthroughs," said ARPA-E Director Evelyn N. Wang. "We identified the need for more effective alternatives to the current battery recycling paradigm. I look forward to seeing how these CIRCULAR projects develop regeneration, repair, reuse, and remanufacture technologies to create a sustainable EV battery supply chain."

This collaborative project pioneers an industry-ready blueprint for the battery facilities of tomorrow by developing an automated battery pack disassembly process; advanced diagnostic protocols for assessing packs, modules, and cells; and refabrication methods for integrating reusable cells into new energy systems. These innovations pave the way for end-of-life lithium-ion batteries to be systematically evaluated, classified, and reused—maximizing their value and extending their life cycle.

"As it stands, this project and program will highlight avenues for everyone to rethink their approach to battery circularity and help prioritize the extension of battery life, facilitate battery reuse, and reduce battery waste while unveiling the appropriate pathways to achieve such priorities," said Nik Singh, principal scientist at the Toyota Research Institute of North America (a division of TEMA), who is the principal investigator of this project. "This is only made possible by the collaboration between the exceptional teams comprised within this project group."

"We're addressing key obstacles in the current battery supply chain with a first-of-its-kind, closed-loop process for end-of-life battery products," Verma said. "We are excited to partner with talented experts across industry and labs to ensure our approach is practical, holistic, and capable of giving new life to old batteries."

As an industry leader in battery diagnostics, imaging, and machine learning, NREL is uniquely equipped to support a critical component of this process: providing diagnostic protocols to extract state of health and remaining useful-life information on recovered batteries. These protocols will be crucial in determining if these batteries should be reused, refurbished, or recycled following disassembly.

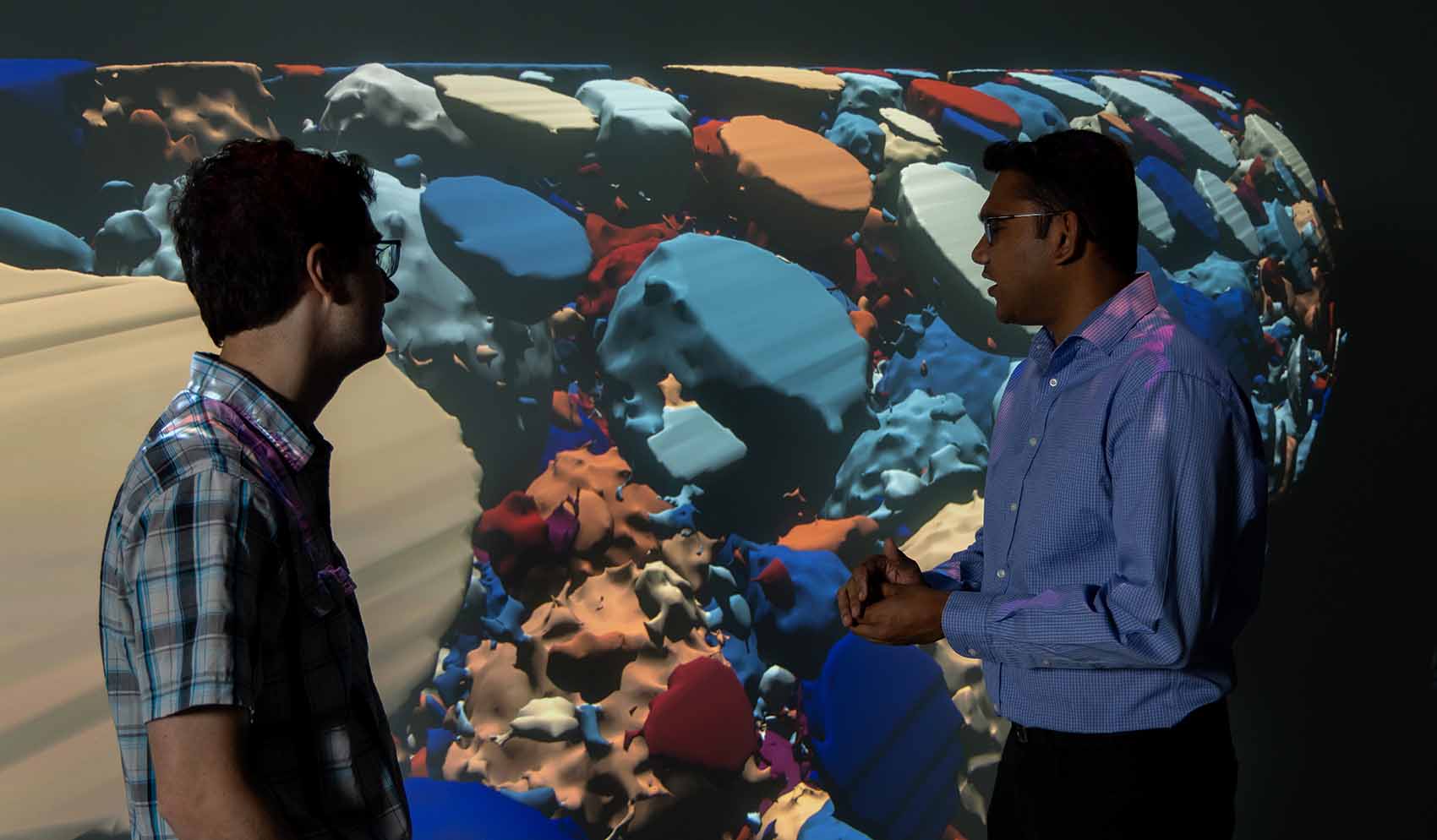

Cutting-edge nanoscale X-ray computed tomography capabilities, along with the NREL-developed Microstructure Analysis Toolbox (MATBOX), play a key role by offering rapid and detailed characterization of battery degradation. By combining electrochemical and imaging data with machine learning, researchers apply a first-of-its-kind multimodal approach to detect subtle patterns of wear and degradation within the battery's internal structure. This analysis can identify damage that has occurred deep within the battery structure to determine which recovery technique would be most effective to extend the life cycle of the battery—paving the way for smarter, more sustainable battery life-cycle management.

"NREL's expertise in advanced electrochemical analysis and imaging allows us to evaluate batteries at an unprecedented level of detail," Verma said. "For the first time, we're combining these techniques to precisely assess a battery's health, making it possible to identify the most effective path—reuse, refurbishment, or recycling—to extend its life and keep valuable materials in circulation."

Learn more about NREL's energy storage and sustainable transportation and mobility research. And sign up for NREL's quarterly transportation and mobility research newsletter, Sustainable Mobility Matters, to stay current on the latest news.