Biosystems Design

From genomes to biomes, NREL researchers are designing biosystems to accelerate the realization of a productive and secure bioeconomy.

Large-scale production of fuels and chemicals from renewable sources is hindered by factors ranging from processes within a single cell to dynamics in a bioreactor. NREL is overcoming these hurdles by employing system and synthetic biology design strategies.

Cell-Free Biomanufacturing and Prototyping

Cell free systems represent an innovative strategy to bypass issues such as product toxicity, diversion of carbon substrate, and undesired byproducts while enabling cutting-edge approaches for pathway and enzyme engineering to facilitate bioproduction. However, these systems still suffer from low productivities owing in part to the effects of free diffusion of intermediates, lack of long-term enzyme stability, cofactor or inefficient recycling rates, and the cost of enzyme production/purification. NREL researchers are developing exciting and cost-competitive routes for producing biochemicals and polymer substrates from a variety of feedstocks using integrated cell-free approaches.

Synthetic Biology

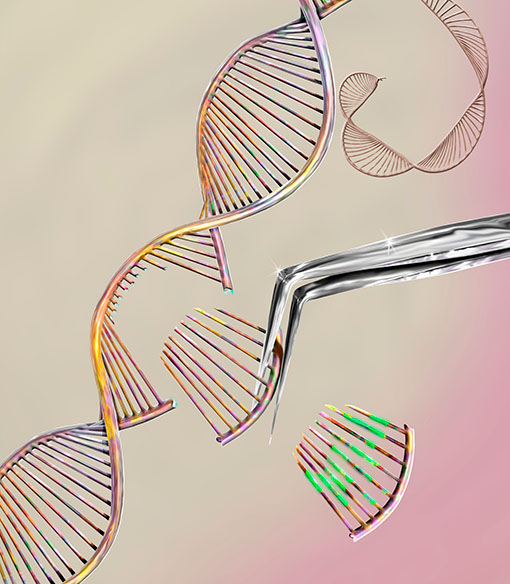

Transformational synthetic biology systems are rapidly advancing biotechnology, a field that is accelerating and expanding the potential of microbial and plant pathways to both established and new-to-nature products. NREL’s Synthetic Biology Platform is leveraging these advances to develop novel intermediates for chemicals and materials, genomically recoded organisms and enzymes with novel functionality, and predictive, secure biosystem designs.

Flagship Projects

We are pioneering cost-competitive routes for producing biochemical and biopolymer intermediates from a variety of feedstocks using integrated cell-free approaches to reduce the risk and costs associated with classical cell-free production. Cell-free technologies show promise for the production of toxic/inhibitory products or products difficult to separate from microbial growth media and, can help reduce the production barriers in multiple areas of biological conversion of feedstocks to biochemicals. This effort will greatly increase the potential for energy-efficient production of chemicals and toxic molecules at scale.

Our cell free and immobilization technologies approaches include:

- Tethered enzymatic systems and reactor/immobilization designs to increase production and separation of problematic biochemical intermediates,

- Constructing expression strains and protein constructs for robust protein production with minimal protein purification

- Enabling the use of artificial synthetic pathways (Metabolons) using new enzymatic routes or enzymatic/chemical catalytic hybrid routes to access new intermediate/product spaces,

- Engineering enzymes to boost stability and operating time, change cofactor specificity or accept cheap biomimetic cofactors

- Strategies to synthesize/regenerate cofactors and mitigate initial costs.

Contact: Yannick Bomble

Our IMAGINE biosecurity researchers develop genome-scale engineering tools to test fundamental principles that drive biological systems, establish predictive biodesigns, and engineer microbes for applications in bioenergy and biosecurity. We work with diverse microbial systems, including phototrophic, methylotrophic, and heterotrophic microbes, to tackle energy challenges. Additional efforts include assessment of risks associated with deployment of genetically modified microbes, as well as the potential impact upon ecological microbiomes, and the establishment of secure biodesigns for safe deployment.

Contact: Mike Guarnieri

Illustration from Getty Images

Working both in vitro and in vivo, we are establishing versatile and efficient carbon dioxide (CO2)-utilizing biosystems for biomanufacturing and delivering integrated, multi-scale design and genome-wide engineering tools to streamline C1 metabolism. These tools are being applied to anaerobic, aerobic, and cell-free testbeds to generate systems-level knowledge, create minimized genomes for biocontainment, optimized C1 conversion, and engineered industrially relevant CO2-utilizing biosystems to produce fuel and chemical intermediates. Our cell-free tools and genome engineering work will enable new capabilities to interpret, predict, and engineer organisms at the systems level, demonstrate safe and efficient CO2-utilizing biosystems that produce a range of chemicals and materials and set the stage to transform biomanufacturing practices.

Contact: Chris Johnson

Significance and Impacts

From cell-free technologies to industrial-scale bioreactors, NREL researchers are developing tools to understand and design systems that can meet the demands of bioproduction.

Contact

Share